Interview by Liz Stevens, writer, The American Mold Builder

Controlling the production flow of a tool build throughout a mold shop requires careful scheduling of job tasks, available equipment and labor resources. On a busy shop floor, that schedule easily can be thrown off as higher-priority orders come through, equipment or material delays occur and employee absenteeism takes a toll.

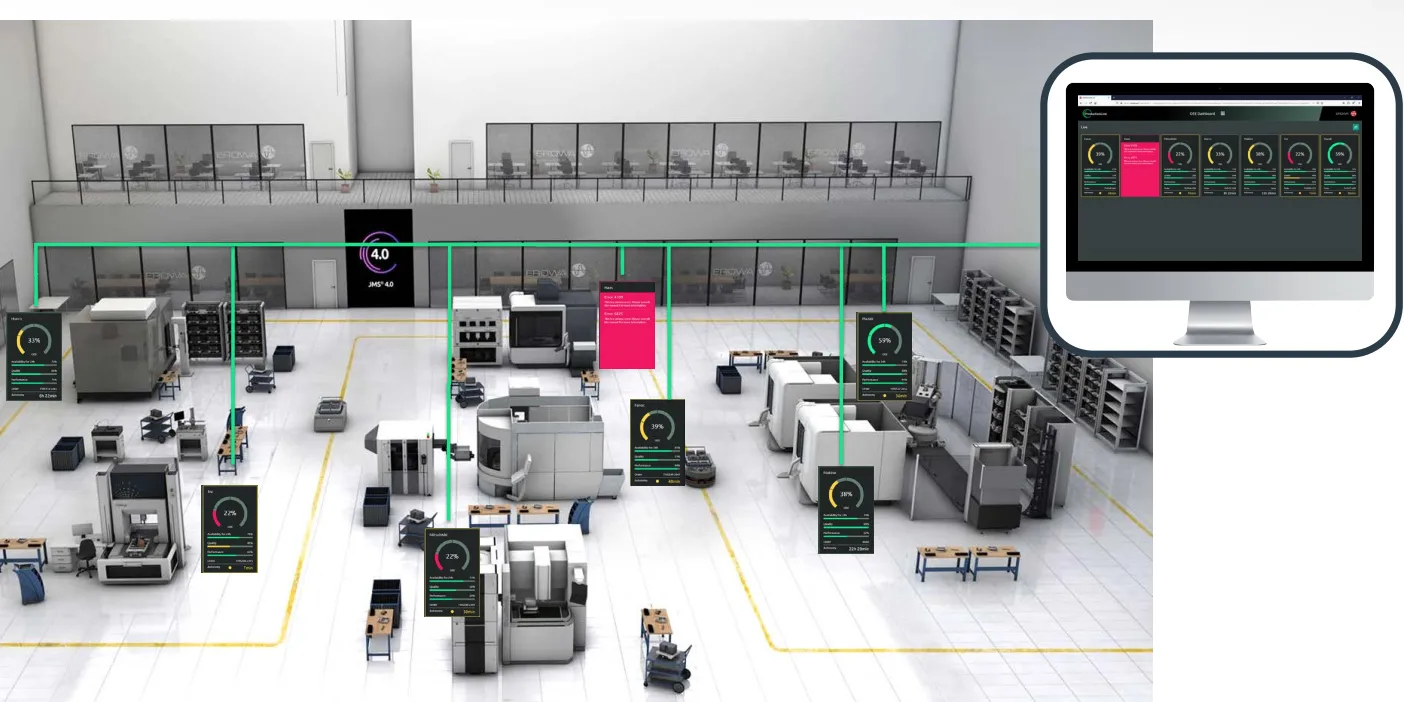

Job management software (JMS) removes confusion and uncertainty by monitoring the cutting tool library of the machine in order to make decisions on how to handle scheduled jobs. It becomes the master of the cell by controlling the machines, communicating with auxiliary equipment (such as robots) and providing data that allows everyone on the job to understand what comes next – whether that’s a manual or automated process – and whether the job will be delivered to the customer on time.

Chris Norman, president and COO of Erowa Technology, Inc., answered a few questions about how job management software can benefit mold shops.

Q: How can software assist with job scheduling?

JMS is the cell controller, using programmed information to know what processes are required to complete a job and organizing all of the work being done within an automated cell. The cell could consist of a single robot and a single machine; it could be a single robot and ten machines; it could be a linear system with multiple machines on different technologies, such as milling, EDMing and part inspection with CMMs. The moldmaker builds the programs – or projects – and then the software uses that data to schedule, monitor and report as a project moves its way through the shop floor. A workpiece is mounted on a pallet, the pallet is stored inside the magazine of the robot and the cutting programs then are managed and stored on a server – but the programs are associated with that pallet and workpiece in the JMS software.

The software doesn’t do this with just one project – it manages all projects in the shop. As the operator builds projects in the JMS, those projects can be prioritized as to which need to be done first and last. Pre-sets can be loaded into the software as well so that once a pallet is put into the machine tool and the programs are downloaded to the controller of the machine, offsets (for example) are downloaded, too.

During the running of the job, the cutting tools that are being used are managed through the machine tool control, but that information also is read by the JMS. So, if a cutting tool isn’t available for a specific part, that part won’t run until the cutting tool is available – but other projects can continue through the production process.

For example, if a mold cavity needs to be cut with a 6 mm cutter and the 6 mm cutter that was in the tool changer of the machine is now end-of-life, the operator can put that mold cavity to the side. Then other jobs that need to be run can be scanned to see if all the tools are available. If they are, the next job can go on the machine and the job that needs a 6 mm cutter will be held until the operator has addressed its end-of-life status. Once the operator replaces the 6 mm cutter and refreshes it in the tool library of the machine control, then the software sees that it is available and that job can be run.

Q: How does the software know where the work-in-progress is in the production cycle?

There are three ways to identify a pallet containing the workpiece. First is a visual link, and that is up to the operator to make sure he has taken the pallet and put it in the right location. Manual link is where a chip is read and then the load station puts the workpiece away. Auto link involves rapid scanning with radio-frequency identification (RFID) tags.

With RFID, each pallet that has a part on it also has an RFID chip that can be scanned to associate that pallet with the job. When the pallet is put into the robot magazines, the magazine is scanned to capture all of the data that is stored in the software.

As an operator, this simplifies the process – once a pallet is set up and scanned in, it can be put into the magazine chaotically, but the JMS still knows what to do because the magazine has been scanned. JMS populates the library view of the software to show where all of the pallets are, which are ready to run, what might be finished and what might be waiting – whether it be tools or programs.

Q: What monitoring can be done while the job is in production?

The software provides an order list, priorities, CNC programs, tool management and the current status messages to give the operator the relevant facts at a glance. Even from a distance, the status of production can be discerned, with color designations that clearly display what is going on.

Operators can monitor all of the alarms that might come up in the machine, as well as in the robot. Some alarms are critical alarms, and some are not; some stop the system, and some don’t. For instance, a low coolant alarm won’t stop the system from running, but it can be sent out via email so someone on the shop floor can address the issue.

The OEE (Overall Equipment Effectiveness) dashboard shows the efficiency status at a glance. All machines in the cell are monitored – their efficiency, uptime and all jobs that have been going through – to provide a historical look at how efficiently shops are utilizing their equipment. Different views provide a clear and structured overview for all production cells, or individually in detail for a single machine.

Q: How does this contribute to efficiency?

It’s all about spindle uptime. When talking about milling machines, mold shops want to know how efficient the machines are running throughout the day. JMS software can break it down to actual runtime, idle time, maintenance time – anything like that can be reported. From there, tool shops can gauge whether they are utilizing the cell efficiently.

If a company, for example, has an automated cell and thinks the cell is overbooked, before that company buys more machines, the first thing it should do is find out if, in fact, the cell is overbooked. The data will show if the cell is running as efficiently as possible.

Mold shops can get 80 to 95% uptime, 24/7 – as long as those shops continue to feed the automation by understanding how to efficiently schedule production. Monitoring the uptime of the machines is the most critical thing software can do to make moldmakers more productive.

Chris Norman is president and COO of Erowa Technology, Inc., based in Switzerland with US headquarters in Arlington Heights, Illinois. EROWA’s JMS 4.0 MoldLine is a universal process control system for toolmaking and moldmaking. The system takes on the planning, controlling and monitoring functions of production plants so it is clear at all times which workpiece is engaged at which position in the process at what time. Erowa’s JMS 4.0 ProductionLine is for chip-cutting machining operations. For more information, visit www.erowa.com.