By Lindsey Munson, editor, The American Mold Builder

In this era of modern manufacturing, molding simulation services and mold flow analysis are pivotal in shaping the virtual effects of a mold to real-world precision, efficiency and cost savings. By using advanced simulation technologies, manufacturers can analyze and optimize the parameters that accompany mold design and production. From the flow of materials to the cooling channels, these tools give engineers and designers the ability to foresee challenges, fine-tune and troubleshoot designs and deliver superior molds that meet or exceed the manufacturers’ standards for performance and durability.

To offer a deeper look and give reality to the complexities, value and innovation behind mold simulation and analysis, The American Mold Builder interviewed three industry experts who collectively have decades of experience in this specialized area.

Increasing Confidence Through Mold Simulation

Danny Branch is a CAD/mold product owner with Cimatron, Novi, Michigan, a company that provides toolmakers with an end-to-end solution for designing and manufacturing tools. One of the old sayings, “Try before you buy,” brings the reality of mold simulation full circle. Branch said, “It’s like performing a ‘mold tryout’ before cutting any steel.” He shared that simulation and analysis allow critical mold design decisions for gating, venting and cooling to be tested and quickly optimized; and that the simulation can be used to verify decisions based on the collective design experience at a shop. “It even can be a big help in educating and guiding the next generation of designers,” said Branch.

The benefits of mold simulation are well-known in the industry; however, it is important to connect the dots as to “why” manufacturers should incorporate this step in the moldmaking process. Branch said, “Experimenting with gating scenarios ensures that parts have the best orientation in the mold, that runner systems are optimized and that the mold itself will be compact and efficient. Having to rework a mold creates extra costs and slows down the other jobs on the production floor. By providing ‘empirical evidence’ for the successful design of specifics, like gate sizes and vent positions, flow simulation helps a shop make decisions that increase the chances of success right from the start. It also can point out potentially severe molding flaws, like visible weld lines, warping or incomplete filling. Identifying these issues early in the process minimizes design adjustments and reduces the cost of tooling corrections. Overall, flow simulation increases confidence in favorable results. It even can reduce the need for physical prototypes – and fewer prototypes translate to reduced material and labor costs.”

Alongside the advantages of mold simulation, Cimatron shared best practices to build structure within the process:

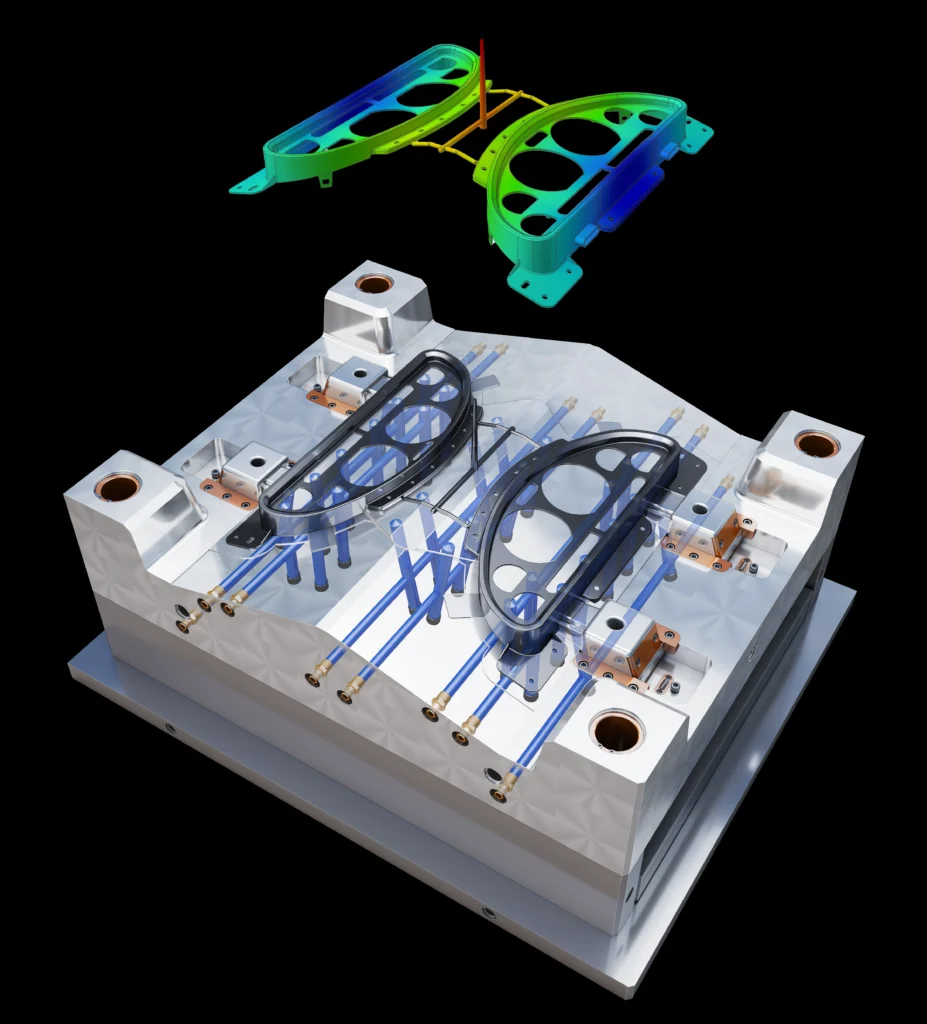

- Run a simulation using the exact material that will be used to mold the part. Branch said, “Simulation software includes access to a large materials database, so if the plastics have fillers or fibers, using the correct material for simulation ensures that the true flow behavior will be estimated.”

- Take time to represent the cavities and cooling lines. This allows the simulation to provide better data about how fast the part can cool and any warp it might experience. “Performing a comprehensive simulation,” said Branch, “means that there should be no surprises when the real mold gets to the press.”

- Adopt an easy-to-use mold simulation solution early in the process. In doing so, it gives a significant advantage over competitors who may be hesitant

to invest.

The results from a mold flow analysis provide metrics for designers and engineers to use (e.g., cycle time, design issues, resource usage) against real-world production, advancing the product from ideation to conceptualization. Branch said, “When performing mold simulation, designers should pay special attention to the fill time, the mold temperatures and the packing pressures – as these values should match the initial assumptions. We often hear only the success stories, but a lot can be learned from simulating a failed mold design. If simulation is used to take a closer look at past mistakes, companies typically find that the results match their real-world experiences – and the solutions needed to fix the problems.”

Branch said, “Especially helpful for toolmakers is streamlined simulation software that reduces the learning curve and empowers toolmakers to achieve ideal results without having to be CAE specialists. Modern simulation software is becoming more like CAD, with user interfaces that are easy to use. Mold designers don’t want to spend time on the mechanics of part quality or mesh density, so simulation software is getting better at importing 3D models and fixing what needs to be repaired before simulation.”

As the molding industry looks to the future, Artificial Intelligence (AI) is an emerging trend that can help inexperienced manufacturers make good decisions and become productive quickly. Using AI in the design phase to automatically detect part features makes the design process more efficient and empowers companies to apply their best practices consistently.

In summary, by helping identify potential design flaws, predict material behavior and evaluate the performance of molds under real-world conditions – simulation reduces the need for “physical tryouts” and helps ensure better results. “Placing trust in simulation software,” said Branch, “comes easily once a company has seen it back up the real-world results!”

A Vital Tool in Modern Manufacturing

Torsten Kruse, founder and president of Kruse Analysis and Training, Naples, Florida, provides innovative, full-capacity filling-to-warpage Computer-Aided Engineering (CAE) simulation services. From idea to finished product, Kruse develops custom injection molding simulations, allowing companies to evaluate essential aspects that impact part moldability before a part is designed and a mold is built. Kruse said, “By integrating CAE mold-filling simulation software into workflows, mold manufacturers can enhance efficiency, reduce costs and deliver optimized part designs and high-quality molds that meet demanding industry requirements. It has become a vital tool for staying competitive and innovative in modern manufacturing.”

“Injection molding simulation software provides manufacturers with advantages that enhance efficiency, quality and scalability,” said Kruse. Here are three

key benefits:

- Reduction in Design and Production Phase Risks

Optimized Part and Mold Design: Simulation software allows manufacturers to predict and analyze the behavior of materials during the injection molding process. This helps identify defects, like warping, sink marks or voids, before the mold is physically produced.

Error Mitigation: By visualizing flow patterns, pressure distribution, cooling efficiency and stress distribution, manufacturers can address potential issues upfront, reducing the likelihood of defective products.

Faster Iterations: Virtual testing enables quick modifications to the design, eliminating the need for multiple physical prototypes, saving time and minimizing production risks.

2. Cost Reduction

Decreased Prototype Costs: By simulating the molding process digitally, manufacturers significantly reduce the number of physical prototypes needed, saving material and labor costs.

Minimized Waste: The software helps optimize material usage and part and mold design to ensure minimal scrap and avoid overuse of raw materials.

Reduced Machine Downtime: Design of Experiments (DOE) simulation insights allow better machine set-up and parameter adjustments, leading to fewer stoppages and lower maintenance costs.

3. Operational Efficiencies and Scalability

Shorter Development Cycles: By streamlining the design and testing phases through simulation and scalability analyses, manufacturers can bring products to market faster.

Improved Process Control: The software provides precise insights into parameters such as injection speed, pressure, packing pressure, time and cooling time, enabling fine-tuned processes for maximum efficiency.

Adaptability for New Projects: Simulation software is scalable and adaptable, allowing manufacturers to handle diverse materials, complex geometries or changes in production volume with minimal disruption.

In addition to knowing the benefits of conducting a mold simulation, Kruse said, “It is essential that manufacturers align and implement several best practices that assist engineers and designers in producing optimal outcomes and efficiencies within their operations. These best practices include accurate material data from suppliers and databases; high-quality mesh that balances detail and computational efficiency; realistic process parameters (e.g., melt temperature, injection pressure, cooling times); comprehensive mold design, as this influences simulation accuracy; boundary conditions to mimic real-world scenarios; validate with physical data from real-world molding trials; consider warpage and shrinkage analysis to predict dimensional stability and ensure final part quality; iterate and optimize by running multiple DOE simulations; collaborate across teams; and leverage advanced features (e.g., fiber orientation prediction, multi-component molding or conformal cooling analysis).

“To evaluate the effectiveness of a mold simulation,” said Kruse, “selecting appropriate performance metrics, aligning the simulation with real-world conditions and leveraging the data for continuous improvements are crucial.” He broke this down into two parts: 1) performance metrics for evaluating mold simulation and 2) guidelines to align simulation results with real-world conditions. Kruse said, “By focusing on these metrics, adhering to validation guidelines and leveraging simulation data effectively, manufacturers can ensure mold simulations are a valuable tool for achieving lean manufacturing goals and continuous improvement.”

If looking to enhance operations and utilize resources in connection with mold simulation software, Kruse said, “The integrations of enterprise resource planning (ERP) and manufacturing execution systems (MES), as well as automated robotics, are growing common in modern manufacturing environments to streamline operations, enhance precision and optimize production processes. If considering such an integration, it is crucial to ensure compatibility between the systems and select software solutions that support open standards and interoperability.”

In thinking about the future of moldmaking, Kruse said, “Emerging trends in injection molding simulation focus on enhancing precision, speed and sustainability. Advances include AI-driven predictive modeling, real-time simulation tools and cloud-based platforms facilitating collaboration and scalability. Enhanced material modeling now accounts for complex polymer behaviors, enabling more accurate predictions of part performance and defects. Additionally, simulations increasingly integrate with Internet of Things (IoT) systems and digital twins, eLearning initiatives, and virtual reality and mixed reality applications, allowing manufacturers to optimize parameters using accurate production data.”

“In the future, this evolution is expected to drive smarter decision making, lower production costs and enable customized solutions with greater speed and reliability, fostering more agile and sustainable manufacturing processes,” said Kruse.

Simulation Solutions for Smarter Production

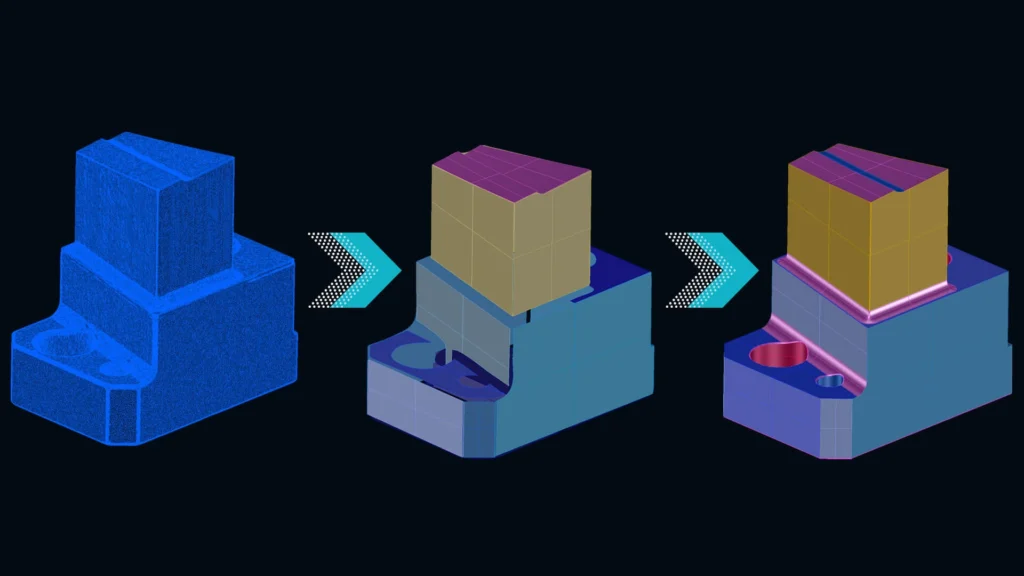

Michael Thiessen is the North American sales manager at Tebis America, Inc., Troy, Michigan, a software company that specializes in CAD/CAM systems for manufacturing and design. “In today’s moldmaking environment, it is crucial to have an accurate and virtual representation of all the available equipment used for the machining,” said Thiessen. He continued the scope of “why” mold simulation is a critical and beneficial process in the developmental phase for manufacturers by covering three main areas, including planning, safety and optimization.

First, moldmakers do not have time to “play around” on the milling machine to see if the part fits on the machine, how many setups are required for the part and what type of tooling or fixturing is required – all so that the mold can be machined without stopping. Thiessen said, “Therefore, accurate virtual CNC machines are used for the ‘planning’ and selection of additional supporting equipment (e.g., work holding fixtures, special tooling). A digital twin is the key to replicating the product or system within the simulation. Not only does the machine need to be represented virtually, but the tooling also needs to be realistic and data-rich, the work-holding solutions need to be parametric and accurate, and every motion that the machine makes needs to be accurately represented (e.g., the tool changer, tool laser, manual tool change positions, traverse motions).”

Second, the cost of milling machines is quite high, and thus manufacturers can’t afford to have mistakes happen on their machines that could cripple production. “If a machine crashes, the cost is not only the repair of the machine, which is quite expensive, but every part of the process also associated with meeting production and customer demands has a huge impact on the operations,” said Thiessen. “This includes the cost to repair the part, the cost to outsource the part/machine to a supplier because there’s not another machine available, the potential risk of not delivering on time, labor and the reshuffling of other parts. These factors play a crucial role in the ‘safety’ and well-being of the company. Mistakes happen, it’s human to make mistakes; however, finding the mistakes early on and rectifying them is priceless. That is what a good simulation solution can deliver.”

Third, a simulation solution, if correctly used, can harbor a lot of information within its model. “It is not just a geometrical representation of the machine – it is much more!” said Thiessen. It can be a storage container of data because it has information on the limits of the machine, the amount of travel available, rotational restrictions, look ahead of the machine controller, acceleration parameters of the machine, tool change location and more. He said, “Knowing which way the machine will rotate when submerged in a deep cavity is crucial. If a mold simulation can ‘optimize’ the movement of the machine, then a manufacturer has the best option to succeed and possibly increase its chances of getting the part off the machine earlier than expected. In addition, if the simulation solution can use this data and provide a highly accurate machine time, then the machine managers can forecast accordingly and schedule one more mold during the day shift. Time is everything for a mold shop!”

As manufacturers look to mold simulation for precise data in the initial stages of mold development, Thiessen shared five best practices:

- Scan the numerical control machine and have a 100% accurate representation available.

- Have a post-processor that mimics every motion of the machine, accurately and dependably.

- Create a virtual tool crib of all tooling and create a standard of these tools to include necessary data (e.g., feeds, speeds, step-over values, step-down values) for the machines.

- Use parametric solutions with work-holding fixtures so that it’s as realistic and adaptable as possible.

- Utilize a software solution that applies an “inline” virtual simulation, not a simulation based on the G-code of the posted output.

“For the future, I see a great use of AI in the world of machining and simulation. We tend to do the same actions that we did about a year ago with some small modifications. If AI was present,” said Thiessen, “then it could define and predict the course of action and strategies to be used for these types of parts. It also could dictate which machine it could fit, and which machine is the fastest for these types of parts. Therefore, integration of AI in manufacturing is crucial – especially due to the knowledge and experience this new workforce harbors. Many of the experienced experts have retired or are on their way to retirement, along with their knowledge. Companies must retain and capture this knowledge so that the NextGen workforce offers the same quality and excellence.”

More information: www.cimatron.com, www.kruseanalysis.com, www.tebis.com