A look at Computer Numerical Control (CNC) equipment, encompassing a set of machines and tools used in the manufacturing processes to produce parts and components with high precision, accuracy and consistency.

HEIDENHAIN

847.490.1191

www.heidenhain.us

HEIDENHAIN, Schaumburg, Illinois, develops, manufactures and sells components for the core industries of machine tools, electronics and automation. It offers the TNC7, which is a CNC system designed to enhance precision machining. HEIDENHAIN provides a user interface that adapts screen contents to the task at hand. Intuitive, task-focused and customizable, the TNC7 allows users to draw contours directly on the touchscreen. Familiar elements like the TNC keyboard ensure ergonomic comfort. The TNC7 excels in task-focused support with advanced cycles, smart probing and 6D-alignment guidance. Reliable process monitoring detects irregularities, while component monitoring protects spindle bearings and detects wear. With predictive maintenance capabilities, the TNC7 ensures high process quality and efficiency, making it an indispensable tool for precision machining.

Hexagon Manufacturing Intelligence

937.668.2578

www.hexagon.com

Hexagon Manufacturing Intelligence, North Kingstown, Rhode Island, is a global supplier of digital reality solutions combining sensor, software and autonomous technologies. Its CNC simulation software builds real-life machining environments before production, assisting manufacturers in avoiding errors, decreasing setup times and switching CNC programs between machines to increase productivity and reduce costs. Hexagon offers NCSIMUL, a CNC machining verification and simulation software that helps validate G-code and optimizes machining processes in a virtual world. NCSIMUL has several benefits, including safe and collision-free machining, reduction in CNC downtime, proving out G-Codes on the computer before

machining, optimization of toolpaths and the ability to run machines unattended.

Makino

513.573.7200

www.makino.com

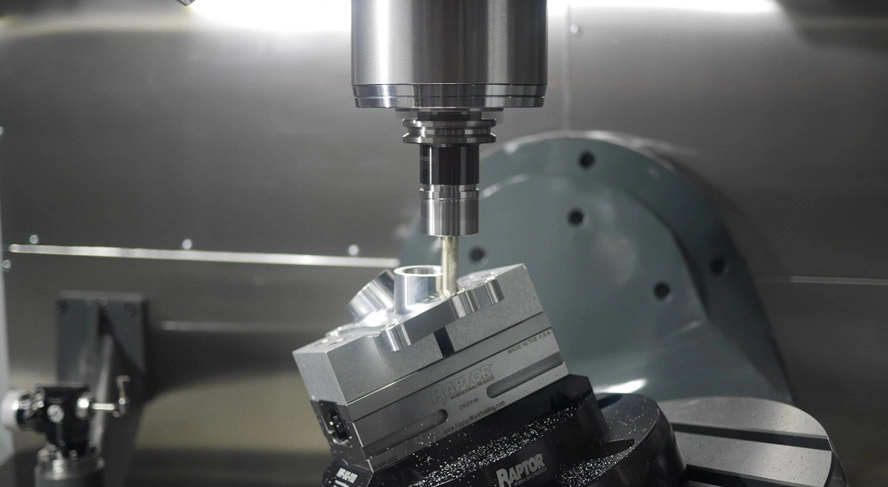

Makino, Mason, Ohio, offers a comprehensive range of solutions, including horizontal and vertical machining centers, wire and ram EDM and graphite machining centers. Its D200Z 5-axis Vertical Machining Center is designed for tighter tolerances and flawless blends and matches in complex 3D-contoured workpieces. The speed and precision of the D200Z supply a foundation for responsive high-speed cutting and surface finishes that reduce or eliminate handwork. Its 30,000-rpm spindle and integral direct-drive table provide quick, precise and full 5-axis machining. This capability is tied together with Makino’s proprietary SGI.5 motion control software for accuracy and quality in the blends, and matches of intricate surfaces and 3D requirements typical of today’s die and molds.

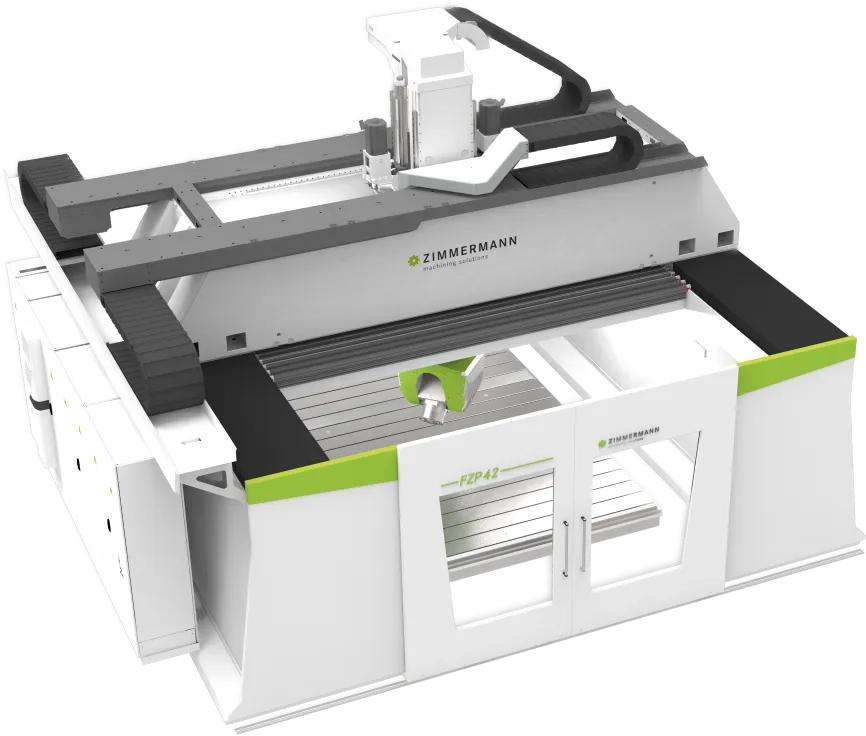

Zimmermann, Inc.

248.305.9707

www.zimmermann-inc.com

Zimmermann, Inc., Wixom, Michigan, is a German precision manufacturer of CNC milling equipment. Zimmermann stands for innovative, high-quality and efficient milling solutions serving customers worldwide. Its modular machine system provides flexibility for individuality, and the thermal symmetrical gantry provides maximum accuracy. Zimmermann develops its milling machines with passion and precision. Zimmermann finds the right solution to fit individual company requirements, the specific industry served and all components/materials that are encountered in the machining process.