By Sujit Sheth, monitoring business manager, Progressive Components

Molds are a molder’s most critical asset. When a mold is not running, – bad things happen – including parts are not being produced, labor is underutilized, revenue is not generated, supply chains are delayed and customer relations can be strained.

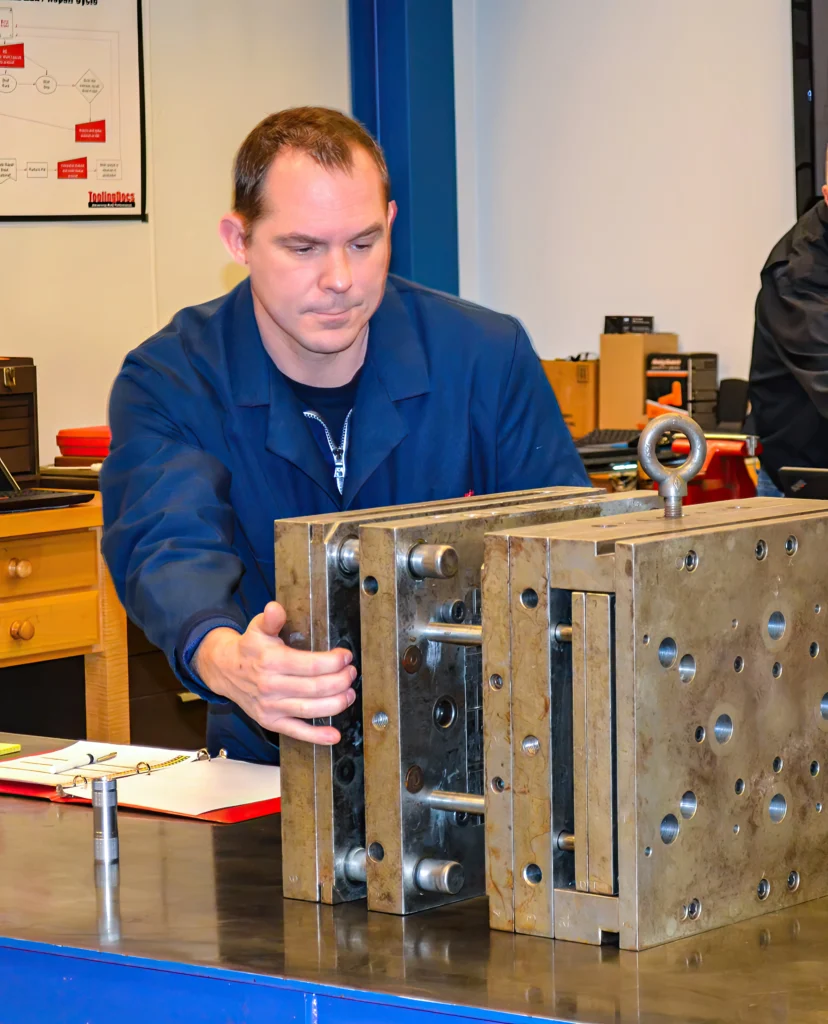

Despite these ramifications, many molders’ toolrooms are under-resourced, with secondhand benches as work surfaces; old, repurposed machinery; and a documentation system that might consist of handwritten notes within a three-ring binder, manual entries into a spreadsheet or an ERP work-order system not designed for maintaining production tooling.

Investing in a preventive maintenance (PM) program will help with more than reducing the negatives from unscheduled downtime. In addition, there are many other benefits that lead to success.

Quality

Regular preventive maintenance ensures consistent product quality. Any wear and tear on the mold can lead to defects in the final products, such as flash, surface imperfections, warping or dimensional inconsistencies.

Cost Efficiency

Preventive maintenance is more cost-effective than corrective measures. Properly maintained molds are less likely to break down, reducing the need for costly repairs, refurbishment or replacements.

Downtime Reduction

Mold breakdowns or failures can result in production downtime, which can be extremely costly. Routine maintenance helps identify and address potential issues before they cause significant disruptions in production.

Mold Life

Injection molds can be expensive to build and repair, so maximizing their lifespan is essential for a good return on investment. Regular maintenance can extend the life of molds, allowing them to be used for their expected lifespan and beyond.

Consistent Cycle Times

Well-maintained molds operate more efficiently, ensuring consistent cycle times. This reliability in production planning helps meet targets without unexpected delays or variations in output.

Productivity Improvement

Maintaining molds at optimal conditions ensures higher utilization by reducing production defects, unexpected mold-related issues and unplanned downtime.

Safety Considerations

Molds in poor condition can pose safety risks to workers. Regular maintenance is a proactive measure that helps identify and rectify potential safety hazards, ensuring a secure work environment.

Scrap Reduction

Inadequate mold maintenance can lead to defective parts, resulting in increased material scrap or sorting costs. This is both environmentally and economically unfavorable.

Compliance with Audits

In some industries, there are strict quality and reporting standards that must be met. Regular mold maintenance can help ensure compliance with these standards and

prevent issues.

Customer Satisfaction

Ultimately, consistency in product quality from well-maintained molds leads to higher customer satisfaction. These customers then are more likely to award new projects to their most consistent suppliers.

Implementing effective preventive maintenance programs offers numerous benefits as outlined. Considering all forms of potential investments – and implementing those that most apply to and benefit your specific tooling needs – is a path to increasing manufacturing competitiveness and long-term company profitability. n

Sujit Sheth is the monitoring business manager for Progressive Components’ Mold Monitoring Division. As such, he works with other team members to develop and implement all products related to asset management and mold monitoring, including the exclusive CVe Monitor, components for ProFile that make remote, real-time monitoring of tooling possible. The monitoring product line also includes System Cooling for real-time monitoring of flow and temperature through every circuit of the mold. With 20 years of experience in the operations and injection molding sectors of manufacturing, Sheth’s experience helps greatly with anticipating and understanding customer needs and the issues they face regarding mold program management.

Progressive Components, Wauconda, Illinois, is a global leader in componentry and mold monitoring solutions for the production tooling industry. Progressive’s off-the-shelf standards speed mold builds and reduce downtime, while ProFile asset tracking and mold management technologies provide exclusive maintenance and asset tracking advantages for molders and OEMs.

More information: www.procomps.com, [email protected]