By Brittany Willes, contributing writer

The American Mold Builder

Solutions after retirement.

“I retired when I was 50. Around the second year of my retirement, my wife famously said to me, ‘I married you for good or bad but not for lunch. Go do something,” Don Dumoulin explained with a laugh. Dumoulin took his wife’s words to heart and began looking at various companies for a possible acquisition. He eventually settled on a mold manufacturing company called Precise Mold and Plate.

The company had been in business for nearly 35 years before Dumoulin took over. In the nearly seven years since he’s been the owner, he’s made many changes, including rebranding the company as Precise Tooling Solutions, Inc. “We’ve done a lot to diversify the business over the last several years,” he stated. “We’ve taken what was essentially a mom and pop operation and converted it into an aggressive, specialty manufacturer. We’ve gained a lot of skills, talents and processes that we didn’t have before.”

According to Dumoulin, when he first took over the company the majority of its business was derived from new molds in the automotive sector. Today, those areas account for less than 50% of the business’s focus. This shift away from the old business model was an important part of creating a more diverse company.

“Every owner worries about being too specialized and too concentrated in either one industry or one sub-segment of an industry,” Dumoulin explained. “When I first looked at the strategic nature of the business, it was all molds. When you go through a downturn – like the industry is going through now with our problems with China – being too specialized is very risky. Precise Tooling is still growing despite the current challenges facing the industry, and that’s because of our diversification. If we were solely tied to the production of new molds, I think it would be a very different story.”

Fighting for US molders

For many manufacturers, it has been a very different story. Last year, when tariffs were suddenly placed on molds and then just as suddenly taken off again, Dumoulin and others in the industry observed a dramatic swing of molds being built in China, then being brought back to the US and then taken back to China.

“Plastic producers all over the country made what I believe to be a bad strategic decision when they took the business outside of the country,” he stated. “When it comes to making tools, the simple fact is that plastic injection tooling makes up less than 3% of a production run on that tool. So, the decision to keep the molding process in the US but move the mold itself offshore – thereby killing an industry – is just a bad strategic decision. I think at some point in time our customers will have to understand that they need to support US mold builders.”

That’s not to say that US mold builders don’t have any support at home. According to Dumoulin, they do. “Quite honestly, many of our customers do support us, and we have a robust industry of mold builders in the US. Still, there are too many who are constantly searching only for the lowest price, and we’ve got to get that fixed.”

One way to fix the situation is through reinstating the tariffs – something that Dumoulin and Precise Tooling are working to make happen. “Tariffs will help level the playing field,” he remarked. “We’ve been working very closely with Laurie Harbour of Harbour Results and the AMBA board to put up a strong fight with the United States Trade Representative (USTR) and others to help us get that business back. Getting the tariffs reinstated will help get our industry back in line. Once that’s done, I think the industry as a whole can look forward to renewed growth and success.”

Diverse manufacturing

W

hile the industry itself has suffered some setbacks, Precise Tooling has managed to keep growing and remain profitable. This can be traced to the company’s insistence on diversifying its skill set and product offerings. According to Dumoulin, the company initially focused on three key areas for expansion and development.

First, Precise Tooling looked to what it refers to as productivity improvement – mainly, a service business that focuses on repairing and performing engineering changes on current production molds. Having a dedicated service such as this has proven to be invaluable for Precise Tooling and its customers.

“It seems like every week we get a call from a customer saying they’ve got a big problem they need help with,” asserted Dumoulin. “So many of our customers are running flat out every day. They need fast turnaround times on repairs or engineering changes. In response to that need, we’ve built an aggressive, reactive team that digs our customers out of problems on a weekly basis.”

The ability to provide quick solutions for customers is due to the company’s team of dedicated craftsmen, some of whom have more than 30 years of experience in the industry. “Our lead toolmakers have seen every problem and every challenge out there,” Dumoulin said. “The ability they have to react quickly, to turn a problem around and get that customer back in production is a real tribute to their dedication to the customer and also to the way we run our operation.”

The second area Precise Tooling focused on building up was its CNC business – essentially, anything not mold related. The business now does a great deal of work for up to 125 customers each year using the excess CNC capacity it has in its shop, turning the CNC area into a profitable and growing part of the business. The CNC business also showcases another development at Precise Tooling – a focus on developing young employees.

Precise Tooling employs nearly 40 craftsmen, 10 of whom make up its CNC team. Of those 10, eight members of the team are under 30 years old. As Dumoulin noted, “In an industry that is plagued with a challenge in finding younger workers to replace the older generation that is – or soon will be – retiring, to have virtually our entire CNC department be under 30 years old, including the leaders of the department, I think is a real tribute to our company.”

The third area of expansion for Precise Tooling came when the company added specialty manufacturing to its business with the purchase of a company focusing on producing ergonomic machine bases and workstations. Not only has this investment allowed the company to expand its range of products and services, but it allows investment in manufacturing workers themselves.

machine bases and workstations.

“Ergonomics in the workplace – in all manufacturing settings and even in tool shops – is paramount. According to OSHA, the average back injury costs a manufacturer roughly $80,000 a year,” explained Dumoulin. (For more information on this topic, see the article on page 34). Taking this into consideration, Precise Tooling has been offering its line of custom-built and engineered ergonomic workstations, tables and machine bases for roughly three years. In that time, it has seen its investment grow by leaps and bounds.

“We’ve had a record year when it comes to building these customized workstations,” said Dumoulin. “Our peer group in the mold industry should be taking a look at this as their lead mold builders age. Having the ability to raise the mold base to the right height will help their workers.”

Ultimately, it also will help the mold industry: Investing in ergonomics for the workplace makes good sense when compared against the cost of lost productivity and labor shortages resulting from painful injuries that might otherwise be avoided.

Specializing in the future

As Dumoulin noted previously, owners often worry about becoming too specialized in an industry sub-segment. However, having expanded its range into several markets, Precise Tooling is able to also specialize in a few niche areas without suffering any negative consequences. One of those areas is that of high-end LED lighting.

“We do business with some 60% of the US lighting market and specialize in LED lighting for automobiles,” said Dumoulin. “That is a very small niche. There are few moldmakers who do specifically what we do.”

Part of the reason there are so few manufacturers venturing into that particular market is the need for specialized equipment. Highly specialized machines and highly technical craftsmen are required to build high-end tools, and many facilities don’t have the capabilities and/or time for such an investment.

For example, Precise Tooling was hearing from customers that high-end LED lighting cannot have electrical discharge machining (EDM) used on it, nor can it have a lot of manual polish. To combat this, Precise Tooling purchased the highest-quality Roeders 5-axis machine. As a result, it was able to virtually eliminate manual polish and EDM work on its lighting molds.

As LED lighting for automobiles becomes more commonplace, the company’s lighting customers have become more sophisticated in their needs. By investing heavily in capital equipment and adding technologies that change the way the company produces tools, Precise Tooling is able to remain competitive in the global marketplace.

that shown in this headlight housing, has led to an investment in

equipment and operator skills.

“The light beam has gotten significantly smaller in recent years,” remarked Dumoulin. “It’s no longer the size of an incandescent bulb; instead, it’s now a microchip that is putting off that beam of light. As that has become smaller, greater precision is vital. That means our skill level has to become more precise as well. We have to have the tools, machines, craftsmanship and the capability to drive those kinds of overall products. We’ve done that very successfully over the last couple of years as LED lighting has become so prevalent in the industry.”

Furthermore, by changing the way it produces tools and adding in more machinery, including automation, Precise Tooling has been able to take a significant amount of production time out of its tool builds. Doing so has allowed the company to lower its costs, which in turn allows it to be more competitive with China and other countries. “It’s been somewhat of an expensive proposition for us, but one that has been worthwhile,” said Dumoulin.

Investing in customer satisfaction

satisfaction in on-time delivery, innovation, customer service

and other areas.

Precise Tooling has come a long way in the relatively few years since Dumoulin became CEO. Part of that can be attributed to the company’s dedication to listening to its customers, assessing their unique needs and determining the best solutions. This is accomplished via a very straightforward method – the customer satisfaction survey. While many businesses may dismiss the use of surveys as a waste of time, perhaps believing their customers won’t be bothered to respond, they’ve proven invaluable for Precise Tooling.

“We started the survey process before I bought the company when I was doing due diligence on the acquisition,” said Dumoulin. “A survey was sent out to see what the customers were saying about the company. The good news was there wasn’t anything negative, but there wasn’t anything immensely positive either.”

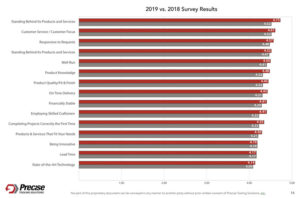

Dumoulin saw this as an opportunity to build on. Initially, the company continued the survey twice a year, asking the same questions each time. This allowed for gathering longitudinal data regarding what customers thought about the business, about the quality of craftmanship and about Precise Tooling’s technology advantage.

“I put our survey results up against anyone in the industry,” said Dumoulin. “Honestly, we get better results than the Ritz Carlton Hotel chain. On a range of 0 to 5, we have every score north of four and we’ve had consistent growth every year in customer satisfaction to the point now that 100% of our customers tell us they would recommend us to a colleague. We feel really good about that. It’s a score that we use to measure ourselves internally, and it’s a powerful motivator for our team because we know exactly what our customers want from us.”

Having previously achieved such positive and helpful feedback from customers, the company now has switched from twice a year surveys to a single annual survey. Additionally, the company makes all of its survey results available online for anyone to see. “That’s how confident we are in the services we provide,” said Dumoulin. “Anyone can visit our website at any time and see firsthand what our customers think and say about us.”

Looking ahead

Despite numerous challenges facing the industry, Precise Tooling Solutions is looking forward to continued growth in the coming years. Thanks in no small part to its dedication to customer satisfaction – which has resulted in investments in equipment, skills and technology – Precise Tooling has positioned itself to meet even the toughest challenges head-on.