By Harvey Lemire, sales and technical specialist

CGS North America, Inc.

I still remember hearing of “5-axis CNC machining” as an apprentice, more than 20 years ago. It was going to be the “future,” saving companies thousands of dollars in time and labor.

I still remember hearing of “5-axis CNC machining” as an apprentice, more than 20 years ago. It was going to be the “future,” saving companies thousands of dollars in time and labor.

The concept itself was exciting to me, but I only understood how revolutionary the 5-axis CNC process actually was when I witnessed a machine in action. Gone were the multiple, complex setups for a single job, and the possible errors in trigging out angles correctly. We no longer had to wonder if the job was picked up properly. All of these worries just seemed to fade away when I was introduced to my first 5-axis CNC machine.

Fast forward to today, the 5-axis CNC machine is a staple in many tool and mold shops, as well as in many manufacturing plants. While these systems were once reserved for complicated and special applications, manufacturers now realize the value of using a 5-axis CNC machine for every project.

Why move to 5-axis CNC machining?

There are numerous factors that support the decision to make the move to 5-axis CNC machining. Minimizing lead times, bolstering efficiency and improving profitability are some of the key factors. The use of a 5-axis CNC machine also will cut the time it takes to complete any given project. A standard 3-axis CNC machine will require several set-ups and changes in work holding: i.e., vices, V-blocks and angle plates. These all require extra time to prepare prior to machining. In contrast, the 5-axis CNC machine is capable of machining five sides in one setup, which translates into considerable time saved.

Another key benefit with 5-axis CNC machining is tooling. Operators are able to use shorter tooling, which aids in longer tool life. It also should be noted that more aggressive cutting parameters can be utilized with shorter tooling, resulting in faster machining.

Using 5-axis CNC machining gives CAD/engineering departments the ability to machine more complex components for molds. When making designs for a 5-axis CNC machine, the CAD/engineering department can cut components that normally would require a compound setup or multiple setups on a 3-axis CNC machine. Since 5-axis CNC machines can cut in a single setup, it translates into CAD/engineers not having to spend valuable time designing a component that is less complicated to machine. This allows completion of increasingly complex projects within tighter timelines.

Everyone knows how much work is involved in a tool build from start to finish. One of the key components of the process is machining. With the use of a 5-axis CNC machine, tool shops not only receive the benefits of faster machining time, but also benefits realized after the machining process is completed. For instance, the ability to remove more material via cutting with smaller tooling reduces the need to use electric discharge machining (EDM) and reduces the need for EDM time in design/cutting of the graphite for this process.

3+2 vs. simultaneous CNC 5-axis machining

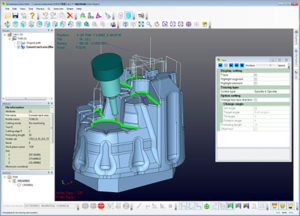

There are two types of 5-axis CNC machining. The first, and most common, is 3+2 machining. The second type, which now is becoming more popular, is simultaneous 5-axis CNC machining. A majority of operators prefer to program using the 3+2 machining option because it is quicker and easier to program. However, there is a push to program using simultaneous 5-axis CNC machining. This achieves a smoother surface finish and a consistent tool path along the surface shape.

Simultaneous 5-axis CNC machining can be controlled in many ways, depending on the CAM software. With simultaneous 5-axis machining, all five axis points are utilized at one time, which aids with better surface finishes and with little to no transition lines. With 3+2 machining, operators choose the axis, view or angle to be cut. This designates where the Z direction will travel. In 3+2, the programmer is required to create a new workplane to establish the cutting direction. There are many ways to create a workplane, and the approach varies, based on the CAM software.

Even with their differences, both 3+2 and simultaneous 5-axis CNC machining are more efficient and quicker than traditional 3-axis machining. CAM-TOOL and other CAD/CAM software companies are constantly trying to make programming 5-axis easier, evolving to control new machine tool technology and adapting to what cutting tools are capable in the tool shop. CAM companies are working on new ways to automate simultaneous functions, requiring less input from programmers. Machine simulation and tool path verification make it much easier to be confident that cutting programs are correct, ensuring that machines will run without issues.

Challenges in adopting 5-axis CNC machining

With changing machine capabilities and software innovations, the knowledge necessary to operate 5-axis CNC machines effectively has become the challenge. Adding two more axes brings more factors into play, such as the risk of potential collisions with tables, sheet metal, fixturing, lasers, etc. These were never an issue with a 3-axis CNC machine.

Finding individuals experienced in programming these machines can be a challenging task. Many companies commonly cater to what their employees are familiar with, due to the employees not wanting to step out of their comfort zone. This is most common when bringing in new software. Employees can see the benefits of switching software and moving to 5-axis CNC machines. However, they have been programming 3-axis with their current software for a long time, and there is an unwillingness to change. Once they have made the switch though, operators quickly see a significant increase in productivity when given proper training and an understanding of the range of capabilities.

In closing, adopting a 5-axis CNC machine increases efficiency and output for any tool shop over traditional 3-axis CNC machining, which requires more setups and tasks the operator with reprogramming for each one. Using 5-axis CNC machining helps reduce production time and labor involved, which translates into quicker tool builds.

No longer limited to complicated and special applications, 5-axis CNC machines will aid in the completion of simple components as well. In my personal experience, having operated a fair amount of 5-axis CNC machines, adopting a 5-axis machine into the shop is the way of the future. Any other shops are bound to fall behind.

Harvey Lemire is sales and technical specialist for CGS North America, Inc., in Ontario, Canada. He has 20 years of machining and manufacturing expertise, including 3-axis and 5-axis machining and 3D surfacing. For more information, call 844.737.6009 or visit www.camtool.com.