by Ed Francis and Chris Engdahl

Crystallume

Diamond has many unique physical properties, and some of those make it an ideal material for cutting tool applications. Of course, it is the hardest known material and is extremely abrasion resistant. In addition, the extremely high thermal conductivity of diamond removes damaging heat from the cutting edge. Diamond’s low coefficient of friction (like Teflon) aids in material flow up the flutes of the coated tools. These thermal and wear properties mean that diamond tools can run at speeds that would destroy all other tools or coating materials. When used at normal speeds, diamond tools operate at a cooler temperature than other tool materials, reducing damage to heat-sensitive workpiece materials.

So, what materials does CVD (chemical vapor deposition) diamond machine well? Carbon fiber composites, metal matrix materials, green ceramics, fiber reinforced plastic and graphite/graphite composites are all materials that rapidly wear out standard tooling, and they also are materials on which CVD diamond has proven its performance. Graphite for molds and EDM electrodes is one of the best applications of CVD diamond cutting tools.

Diamond is not for everything though: It will not machine any of the ferrous materials, due to a chemical reaction between the iron in these metals and the carbon atoms making up the diamond film. And no – it is not the answer to all titanium problems – though diamond tools can machine it, it has never proved cost-effective.

The ideal CVD diamond tooling applications are those in which machining the material forms powder or small grit. These are situations where the primary operation at the cutting edge is basically abrasive wear, rather than chip formation. A material such as graphite is a perfect example.

There are several ways that CVD diamond is produced: hot filament (HF), microwave and torch. Hot filament and torch are used to grow large, flat areas of CVD diamond. Microwave will grow higher quality diamond with fewer defects, which can be used in optics, electronics and gems. This article will primarily involve hot filament, since it is the process utilized to produce the CVD diamond coatings that are used on the cutting tools. This method involves putting the tools in a vacuum chamber (similar to an overgrown toaster oven), then growing the diamond crystals on the surface.

Tool material

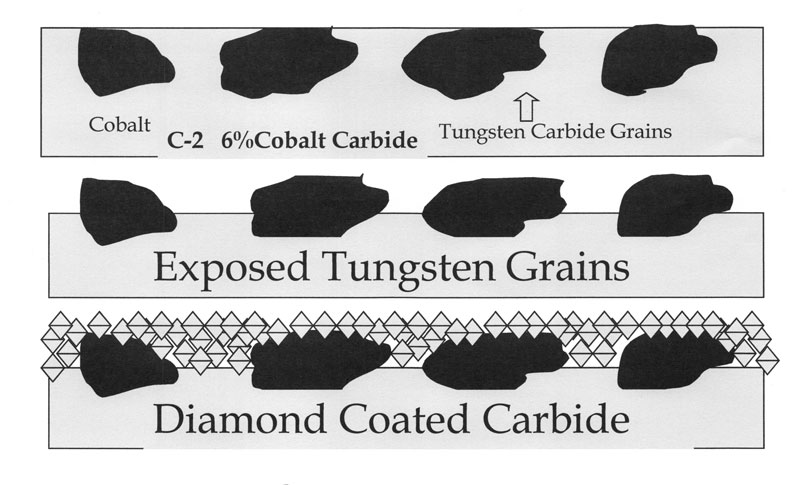

Selection of the proper tool material is crucial to the success of the diamond coating process. The prolonged high temperature necessary during the coating process will damage all but cemented tungsten-carbide and ceramic cutting tool materials. And, for the optimum coating adhesion, a C-2 grade of tungsten-carbide must be used (six percent cobalt binder, tungsten carbide grain size above one micron).

Once the correct material is obtained, the tool grinding must be carefully performed. Any overheating of the tungsten-carbide during grinding operations (burning) will damage the carbide surface and cause the diamond film to flake off the burned areas.

Coating process

Careful preparation of the tungsten-carbide tools before diamond coating is another key to consistent performance. The parts to be coated are carefully cleaned and then typically put through a two-step chemical preparation. The first step roughens the carbide surface for improved mechanical adhesion, and the second step removes cobalt from the surface, since it is poison to diamond growth.

Next, the parts are loaded into the chamber containing hydrogen and methane gasses. A series of tungsten wires, heated to over 2,300°C (4,172°F), are used to provide the energy necessary to both break up the gas molecules and heat the tools to over 750°C (1,382°F). When the proper conditions are achieved, the activated carbon atoms can recombine into crystal carbon and grow together to form a pure diamond film over the entire tool surface.

During the initial growth phase, the carbon atoms will form diamond crystallites in the crevasses between the tungsten carbide grains. These crystallites will grow to form a continuous film that is both mechanically interlocked with the etched tungsten carbide structure and chemically bonded to the carbide grains.

This coating process is very slow, with typical film growth rates of only .5 to 1.5 microns per hour. Since functional coating thicknesses range from 2 to 40 microns, this can mean very long growth cycles of two days or longer. While the typical coating run for a PVD-coated tool is several hours, most diamond-coated tools are in the chamber for one to two days. This is a reason for the higher cost of diamond-coated cutting tools.

Another unique advantage of the CVD diamond-coating process is the ability to grow a wide range of surface structures and optimize the film for a given application. When tool edge sharpness is a primary issue, the diamond film can be grown thin and very smooth. If abrasion is the main wear, mechanism and thicker films are needed. Growing a faceted surface has been shown to reduce the cutting forces and increase lifetime.

Types of diamond-coated tooling

Most any tool that can be ground in the correct grade of carbide can be diamond coated. If the diameter of the tool is greater than 0.008″ (0.20mm) and not larger than 0.500″ (12.70mm), it will usually make sense to diamond-coat the tool. Larger diameters can be coated, but it is usually more cost-effective to use insert tooling for these larger diameters. Most tool companies either stock diamond-coated cutting tools or can manufacture the tools for customers.

Recommended machining conditions

If a plant is already using tungsten-carbide tooling, it effectively knows how to use CVD diamond. It requires the same setup as tungsten-carbide for optimum performance: rigid tool holding, high-quality spindles and solid workpiece fixturing. But remember: The diamond cutting edge can survive a much higher temperature, so the tool can be run at a higher spindle speed. The basic advice is to run at the same chip load per tooth, which – due to the higher spindle speed based on feed and speed charts supplied by the manufacturers – will net a much higher feed rate in inches per minute. The full range of cutting speeds and feeds for specific materials is available on the websites of all the major CVD diamond tool coaters.

Applications

A diamond-coated ball end mill was used to machine a POCO 200 graphite electrode at 940sfm and 315ipm. The previous tool was a TiN-coated carbide end mill. The machinist saw a 15 times improvement in the tool life. Due to the diamond-coated end mill wearing so slowly, the machinist found it easier to maintain the tolerance call outs of the electrode. In this application, the customer benefited from the increased speed at which the part was machined and a net cost savings, since the diamond-coated tool cost six times the cost of the TiN-coated end mill for 15 times the life, faster processing and fewer tool changes.

A metal die caster was machining a graphite mold out POCO 3 with a diamond-coated end mill at 940sfm and 200ipm. This proved to provide a 13 times improvement in tool life over a TiN-coated end mill. The use of the diamond-coated end mill also allowed unmanned overnight operation.

A small shop with a retrofitted Bridgeport-type mill also found advantages for using diamond-coated tools in machining graphite. The shop owner found he could set up several blocks of graphite on the table and set up the machine to run unattended overnight, thus almost tripling the machine’s output. Since the diamond-coated tool wore so slowly, he had no problems holding the tolerances on the part. He did not have high spindle speeds available, but he did have a large quantity of parts to make – which made the use of a diamond-coated tool a sound investment.

Economics

And so, is it worth it? CVD diamond-coated tools are typically priced at four to six times the cost of uncoated tungsten-carbide tooling, but the lifetime of the tool can increase 10 to 20 times. This translates into net tooling cost reductions from 40 percent to 80 percent. Additionally, the increased tolerance control and uninterrupted machining can have a big impact on overall productivity. And, if the spindle is capable of high speeds (+15,000 rpm), full advantage can be taken of CVD diamond’s properties to increase production rates.

Conclusion

Like any new product, CVD diamond tools will need to prove their value on the shop floor before they really make sense to those considering them. But, CVD diamond has become a mature technology and has the potential to dramatically reduce tooling cost and perhaps solve some problems at the same time. There are now several companies producing diamond-coated tools for the die/mold industries. Many of the standard tools in use today can be found listed in the catalogs of end mill and diamond-coated tool companies. If a toolmaker is willing to provide carbide tools ground from a suitable grade of carbide, the major diamond coaters will usually coat those tools as free samples for evaluation in an application.

Ed Francis is vice president, Imagineering, for Crystallume. He has more than 30 years of experience in the cutting tool industry and can be reached at efrancis@crystallume.com. Chris Engdahl is vice president, technology, for Crystallume. He has more than 25 years of experience in coating development and can be reached at cengdahl@crystallume.com.