by Dianna Brodine, managing editor

The American Mold Builder

Profits are increasing. Major consumer brands are on board as long-term, committed customers. An experienced management team is in place and working together. So, why bring in a consulting group to assess the business and its operations? Ask Michael Bohning, owner and CEO of Creative Blow Mold Tooling in Lee’s Summit, Missouri.

High-visibility customer base

Founded in 1984, Creative Blow Mold Tooling specializes in molds for consumer and industrial products, including medical and healthcare products, personal hygiene, household and cleaning products, food and beverages, industrial and agricultural chemicals, and motor oil. Many of its customers have been with the company for 20 years or more, and the highly visible brand names represented on the customer list value both the quality and responsiveness provided by Creative’s 38 employees.

“You can walk down an aisle in any store and see what we do,” explained Bud Carmen, vice president of operations.

In 1985 – on his 18th birthday – Carmen began his first shift at a Creative Blow Mold Tooling facility in California. “Years ago, Creative had facilities across the US, but technology outgrew the business model,” he said. “CNC machines became more expensive and shipping costs went down, so there was no longer a need to have a facility in every region.” As operations were consolidated, the Lee’s Summit facility became the company headquarters and, eventually, sole location.

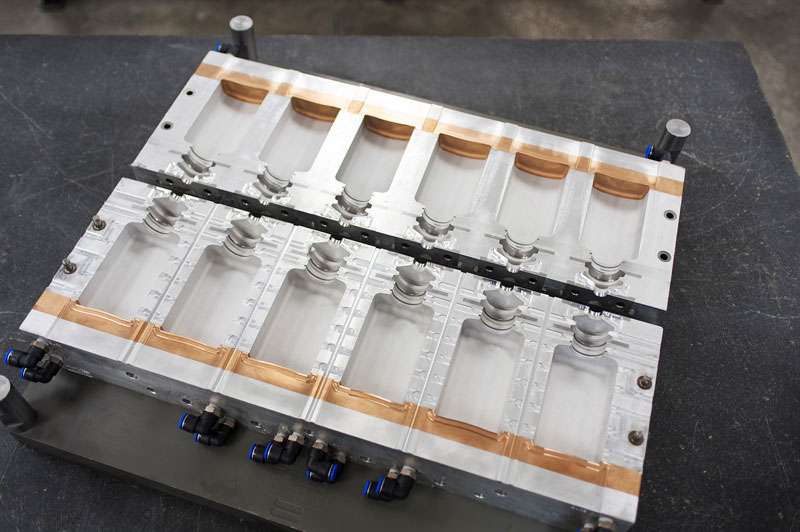

The molds built at Creative are used to produce a variety of plastic bottle types and shapes, and product examples can be found in food products, personal care, laundry detergent, motor oil and pourable cat litter containers. “Our niche is in the five- to six-gallon size,” Carmen said, “but we build molds for bottles as small as three ounces and as large as 30 gallons. Run sizes can be in the thousands or millions.”

Creative works with its customers early in the design process, starting with product design and engineering, before developing prototypes and moving into tool fabrication. According to the company’s website, molds are machined to finish wherever possible, minimizing polishing for better productivity, accuracy and consistency. Beryllium copper and hardened tool steel inserts are used in critical areas for durability and improved thermal transfer.

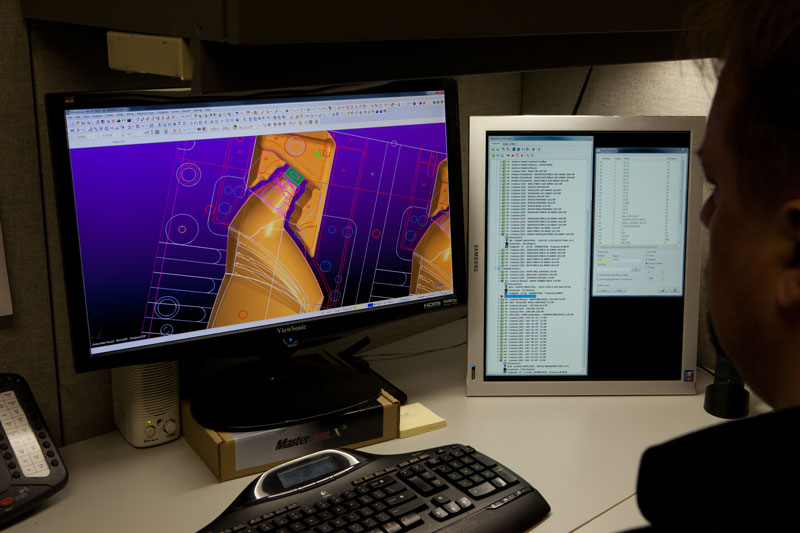

“We have a team of four design engineers,” Carmen explained, “and they work with our customers to take potential design modifications, complete redesigns or entirely new concepts from an idea to a completed 3D computer design.”

Because shelf appeal is critical, additive manufacturing often is the next step to ensure the design will satisfy the consumer appeal requirements.

Product design changes are frequent, driven by the need to attract consumer attention on a store shelf that can be cluttered with competition. The imperative to draw the buyer’s eye in a display means a constant stream of new quotes and production deadlines for the staff at Creative at a pace that can be hectic, but gives the tooling company an opportunity to shine. Three production shifts ensure tight timelines can be met.

“Quality, on time – it’s what we’ve built our reputation on,” said Carmen.

Assessing business operations

Given the continual influx of new business and strong loyalty from its customer base, Creative Blow Mold Tooling is in an operating position many tool builders would envy. Owner Michael Bohning, however, decided to take a deeper look at the business – and he brought in a team of consultants to make it happen.

“I wanted to understand where our opportunities were to improve,” said Bohning. “Where should we focus in order to become more efficient, increase throughput, build capacity and expand our bottom line?” He added, “We want to continue to find new relationships and new customers. The assessment can be a starting point for changes that position this company for more growth.”

In November of 2016, Bohning invited three representatives from Harbour Results, Inc. (HRI), Southfield, Michigan, to conduct a two-day facility assessment. HRI focuses heavily on the moldmaking industry, helping small- to medium-sized businesses understand the strengths and weaknesses within their operations and then developing a roadmap to meet the company’s goals from operational, performance and financial perspectives.

The HRI team examines nine areas of assessment: materials, human resources, engineering, program management, sales and marketing, quality, management, operations and finance/administration. By speaking with employees, reviewing company metrics and observing business processes, more than 600 questions are reviewed to provide an overall “scorecard” based on benchmarked data.

“Over the two days of the assessment process, we’ll gather data to help us assign a score,” said Mark Shircliff, senior consultant for HRI. “The score helps to identify the gaps in the company’s performance, which gives us a starting point for providing recommendations to close those gaps.”

This is not a softball lobbed toward home plate – typical assessment scores are in the low 60s on a scale of 100.

Following the process

On the first day of the assessment, Bohning admitted he wasn’t sure what to expect from the process itself, but he was clear about what he wanted to discover.

“The assessment is a newer offering to AMBA members,” said Bohning, “so I wanted to lead the pack in taking advantage of that. We haven’t had an outside perspective in some of the functional areas of our business, and there’s value in seeing an object through someone else’s eyes. We’re making investments in the company, but are we making the correct investments? Are we as profitable as we should be? Where can we improve?”

In 2009, a facility expansion added new quality assurance and manufacturing space at Creative’s location in a business park. A dedicated salesperson was hired, which has led to new quoting opportunities and additional investments. New employees were added to the engineering team to bring solution-based designs to customers and prospects. Technology advances were brought in house, including a new coordinate measuring machine (CMM) for the quality department, flow simulation to assist customers’ production analysis and scanning equipment to simplify reverse engineering. Increased capacity is the next step in the plan, with new CNC machines, including a second 5-axis mill, already on order.

“We’ve tried to grow in a smart way,” said Bohning, “but I felt we could be missing some opportunities if only tooling could be completed on faster, more compressed time schedules. Is there more we should be doing?”

Carmen added, “We know there are great opportunities in the market segments we already operate in, but there also are areas we have our eyes on for expansion. What needs to be done to prepare before we try to enter those markets?”

The assessment process is meant to answer those questions. In addition to the busy hum of production and ringing phones, the Creative management staff made time to speak with the HRI team while performing its day-to-day activities.

“We want to talk to key employees – find out what they know and what they feel about their responsibilities and the roles they play in the business,” Shircliff explained.

The HRI team was visible on the production floor, in the quality area and in the engineering department. Questions were asked about everything from order entry and shipping to leadership philosophies and human resources paperwork. “We take a look at processes and procedures, and we watch to see where there might be bottlenecks,” Shircliff said. “From there, we can help the company identify the opportunities and create a roadmap to get where it wants to go.”

On the second day of the assessment, the management team at Creative Blow Mold Tooling assembled to review the assessment results. The presentation began with an overall view of where North American mold shops score on a variety of metrics. Then, more detail was provided on where Creative Blow Mold Tooling stood in relation to the averages. From there, three specific areas of attack were identified that could yield immediate, positive changes.

One area of opportunity, likely of interest to many toolmakers, was in setup downtime. A more efficient changeover process while moving one mold out of a CNC machine and another into position could dramatically increase production throughput.

The HRI team asked questions of the experts in the room – the Creative management team – including: Do you trend actual setup times? Do you flex people to assist with setups? Could there be a better use of fixtures? Is the communication between shifts and operators sufficient to avoid downtime/confusion?

Taking the next step

A two-day assessment allows only a glimpse into the daily successes and struggles of a production facility, but the identification of areas of opportunity can provide much-needed focus. Benchmarking the progress of one company with those who lead the industry quantifies how much – or how little – effort needs to be directed to each area, and having a specific target to attack as a team paints a bullseye that everyone can work toward.

“In the last five years, we’ve nearly doubled our volume – from 3.5 million in 2011 to almost 6 million this year,” said Bohning. “It’s apparent we’re moving in the right direction, and the industry is growing, too. Taking the time to assess where we are now and what’s keeping us from getting to where we want to be is the smart step to take.”