By Dianna Brodine, managing editor

The American Mold Builder

Editor’s Note: In the Spring 2016 magazine issue of Plastics Business, I interviewed two Manufacturers Association of Plastics Processors (MAPP) member companies that had utilized 3D printing for recent tooling projects. One of those MAPP members – Polymer Conversions, Inc. – also is a member of the American Mold Builders Association (AMBA). Tooling inserts manufactured via the 3D printing process could be viewed as a threat or an opportunity for mold builders. By sharing the molders’ experience, The American Mold Builder audience can make its own assessments.

This article has been modified from the original.

Two injection molders, both based in New York, are working to circumvent the extended lead times and additional costs surrounding the research and development process of new product launches. 3D printing offers the ability to create insert tooling to increase the level of service offered to their customers and, while neither is looking to replace skilled mold builders as valued parts of their businesses, the possibilities of the technology can’t be denied.

Natech Plastics looks for an advantage

Natech Plastics, Inc., located in Ronkonkoma, New York, is a provider of custom injection molding and contract manufacturing focused on the medical, electronic and consumer markets, with a reputation for research-based experimentation. The company prides itself on its engineering and technology-driven production environment, and CEO Tom Nagler has devoted time and resources over the last two years to watching the developments in additive manufacturing. “As we talked about engineering services being a larger part of our business, we had to talk about how additive manufacturing would fit into that,” he explained. “It was never compelling to me for prototyping, because I can get that done with a service bureau just as quickly and at around the same cost. So, where did it fit? And, what’s the value to our customers? It’s not that compelling of a story if we just print prototype parts. But, maybe there was some value if we could shorten the timeline or test out complex components.”

Mold building as a competitive advantage

Natech’s founder, Gerd Nagler, trained as a master toolmaker before emigrating to the United States from Germany, but Natech Plastics outsources a majority of its mold building to other US toolmakers, applying Gerd’s knowledge to the relationships Natech has nurtured over the years. Working 100 percent domestically is an important differentiation point for Nagler, and he believes it’s a competitive advantage. “Relationships are incredibly important to the mold building supply chain,” he said. “Every year, we specifically devote effort and time to find the right tool builders and develop the relationship with them. It’s a critical part of our business.”

Nagler explains this relationship because he isn’t trying to replace toolmakers with 3D printing. In the same way he offers an expectation of partnership from Natech Plastics to its customers, he also believes the mold builders his company works with are partners bringing crucial skills to the process. Instead, additive manufacturing technology could play a supporting role – and Nagler was intrigued enough to start a few experiments to better understand both the possibilities and the drawbacks.

The beginning of the experiment

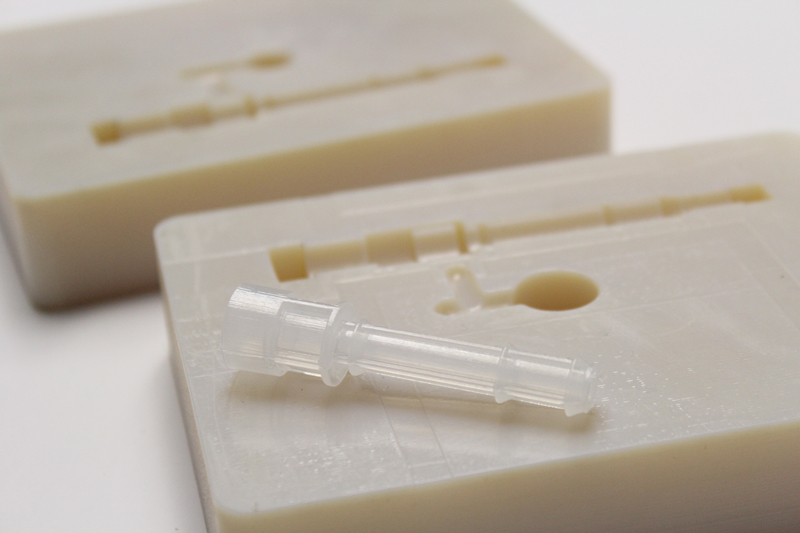

Natech Plastics was near kickoff for the steel mold build of a complex part that was one component of a larger diagnostics assembly, while at the same time another portion of the component was being modeled. Because of the difficulty of the build, Nagler knew a sample with a shorter lead time would be beneficial. “We specifically chose something that was difficult,” he said. “We felt if the insert molding process couldn’t help us through something like that – geometrically complicated, with internal core pins and a detailed exterior – there wasn’t value.”

Nagler looked for a partner, and CADD Edge, a reseller of Stratasys equipment located in New York, was chosen to print the tooling inserts. By exchanging Natech’s engineering and processing expertise with the 3D printing expertise of CADD Edge, the envelope of knowledge is pushed and both companies benefit. “We’re building a database that tells us where the benefits are and where they are not,” said Nagler.

It took three to four iterations to build a useful piece for the initial project, and Natech didn’t beat the original lead time as the company had hoped because of the learning curve. Since the client hadn’t been told a shorter turnaround could be possible, no one was disappointed – and the data gathered was a definite step in the right direction. “We were able to confirm how much the part would shrink, which provide a good benchmark,” Nagler explained. “We also learned how to reduce ovality in cylindrical parts. Those are two things that are not exactly clear to begin with, and now we have that information in a database.”

“In the end, that first part wasn’t all we wanted it to be,” Nagler admitted, “but it certainly wasn’t a failure. Did it realize its promise? Well, it’s a nice story. The learning surrounding the experience was good. I’m not 100-percent convinced where the value in it lies, but I am convinced there’s enough there to continue – to see what else we can learn.”

Natech Plastics has started a second experiment, this one a polypropylene application with a breakaway feature that Nagler calls “a risky design element.” He explained, “3D printing the mold insert gives us a chance to test a feature out. It looks great in CAD, but I don’t want to wait to find out if it actually works. There’s always a difference between what you see on screen and what you see in plastic, and it’s nice to see that now rather than eight weeks down the road.”

The learning curve

Nagler admits the experiments have been fun, but the reality of getting a client to actually pay for it? That’s still unclear.

“All of this is only meaningful if you are a design partner for your clients, not a molder,” he said. “However, we could either wait for other people to learn all there is about 3DIM – and then lose the value to our clients – or we could get the knowledge ourselves and create value. In the end, it’s still about the clients we chose and the strategy we put in place.”

Natech Plastics is on the brink of an expansion plan, and Nagler and his team are deciding whether or not to bring additive manufacturing equipment in house. “At the moment, I think the process has limitations, and that’s why some are staying away from it, but we were able to adjust from one set of inserts to the next because we’re processors and mold builders. Our engineering expertise gives us an edge.”

Polymer Conversions adds to its knowledge of molds

Four hundred miles to the northwest, in Orchard Park, New York, the team at Polymer Conversions, Inc. is engaged in a similar investigation. Engineering and tooling expertise have positioned Polymer Conversions as an innovator in the medical device, healthcare, pharmaceutical and aerospace industries where regulatory requirements can stall large-scale production until extensive testing has been performed.

Reducing the costs of R&D

“We’re a high precision molder,” explained COO Ben Harp, “and we like making parts with critical dimensions. Those dimensions lead to very expensive tools. One of the things that deters research and development is the cost to look at different design concepts and make changes, but the advent of 3D printing has shifted the landscape. Now, OEMs can hold design possibilities in their hands – they can feel the part and connect their thoughts and concepts to reality.”

Prototype printing, however, has its drawbacks. Specifically, material limitations often mean the 3D-printed part is not created from the intended material, so chemical resistance and strength characteristics are not a match. The perfect scenario would provide samples with the faster speeds and lower costs offered by additive manufacturing technology, but that could be used for early stage clinical trials. Polymer Conversions has a complete tooling department on site, so the company’s engineers began to explore the possibility of 3D printing the tooling inserts, rather than the end use part, to create the geometry needed in a shorter time frame without compromising the base materials.

“The best case scenario is to have the ability to take the customer’s design, print an insert tool within 24 hours and drop finished molded parts into the mail for the customer 24 hours after that,” said Dan Schwab, lead mold designer. “What we’re attempting to do is great in concept, but what can we really achieve? Will it work in all materials, and what are the tolerances we can hit?”

Much like Natech Plastics, the team at Polymer Conversions is focused on data collection. There are questions about cycle times and how much heat and pressure can be applied before the insert blows apart. “What we hope to accomplish in this exercise is to better understand what can be done, to what tolerances and resulting in how many parts, so we can coach the customers in what to expect,” said Nathan Greene, process engineer. “For a very low cost, we can get them further down the design path in product development or a small-volume application. We add significant value by saving the customer money.”

Investing in the possibilities

Polymer Conversions does not have 3D printers on site; instead, the injection molding company partners with Staub Additives, a high-tech organization only four miles from its plant. “Our toolroom is capable of building every tool we supply to our customers,” said Schwab, “but we’re prioritizing the support of our production floor for existing tools. At some point, we may invest in additive manufacturing equipment, but now it makes sense to work with a company that already has the equipment and the expertise in 3D printing.”

Harp explained, “What we’re trying to do is take our affinity for learning things and applying technology we already know well to benefit our industry sector. Medical device companies are having early stage success validating 3D-printed medical devices, but you can count those FDA approvals on one hand. We think this is a step better because we’re using legitimate production resins. In medical manufacturing, the faster we can meet our customers’ needs – safely – the faster their devices can be put to use.”

The experiment

For one of its first projects, the team chose a part it has been molding in the conventional manner for 10 years. The learning process will come with an extensive paperwork trail that includes timelines, costs, tolerances and run sizes. Steel, aluminum and 3D-printed tooling will be compared in great detail to provide data the Polymer Conversions’ team can use to then prove results with the customer.

“We know exactly what we can do with eight-cavity tooling,” said Greene. “We know exactly what the part costs to build in the highest quality materials and in less expensive materials. And, we know which materials have been successful. Now, we’ll try out production with insert tooling, and we’ll learn.”

The team’s “internal science project” has produced approximately 300 parts and endless amounts of data on clamp tonnage, venting methods, cycle stability and more. Greene emphasized that the process is what is important right now. “We’re documenting everything we do,” he said. “We keep 99 percent of the parts every time, even if it’s a bad part. Then we label it and document what happened during that test so we can learn what’s possible.”

Takeaways for the mold building industry

Creating insert tooling for a ready-made mold base is an accepted method of reducing the overall costs of production tooling while still incorporating the skills and knowledge of the experienced mold builder. When “printing” those inserts with 3D printing equipment, an in-depth understanding of potential mold performance issues is perhaps even more critical. Toolmakers could have an opportunity to expand the value they offer to their molding customers if they, too, begin exploring the possibilities.

“It’s my opinion that a tool shop today should have its eye open to additive manufacturing,” said Harp. “There’s an opportunity for toolmaking as we know it to be vastly different five years from now with additive manufacturing, and we’re preparing our own facility for that by running R&D projects alongside traditionally built tools that already have shown proven results.”

Nagler also believes the future could be bright for use of 3D printing in mold building, but it’s not a substitute for the traditional process – yet. “This is definitively not a replacement for single cavity molds; instead, it is for work earlier in the development life cycle where either significant technical or economic uncertainty exist,” he said. “It can help dramatically reduce that uncertainty at relatively low cost, but does not obviate the need for more robust tooling once those questions have been answered.” However, Nagler sees potential in a more recent project. “We’ve sampled inserts of another material type and are on our way to overcoming one of the key drawbacks we’ve seen in 3D insert molding: poor parting line and fill performance resulting from an inability to clamp with sufficient force. If we can overcome that, my answer might be different.”

At Polymer Conversions, the laser sintering process also has attracted the attention of its mold builders. “Laser sintered additive metal techniques provide longer term tooling solutions, with less waste and a reduced supply cost,” said Harp. “It allows engineering solutions for more efficient cooling lines that aren’t possible with today’s tooling methods, which result in potential cycle reductions that are significant to improve profitability for the business and the customer.”

Both Harp and Nagler are clear – the technology solution that offers the best outcomes for customers must be pursued. And, mold builders are natural partners in understanding the capabilities as the technology is explored. “Every tool shop is going to run into a huge talent gap in the next five years,” Harp said, “and today’s new hires may not have traditional mold building skills, but they understand computers and programming, which are the basis for the 3D printing process.” With additive manufacturing, mold building businesses have the chance to groom future toolmakers with both CAD programming skills and the critical understanding of mold building offered by those versed in the traditional techniques.

“Ultimately, I think that as a group – engineers, mold builders and plastics manufacturers – we need to stay in front of additive manufacturing as an important part of the design process,” said Nagler. “Increased awareness requires work, but it yields value in the knowing.”