By Brittany Willes, contributing writer

The American Mold Builder

Henry Ford first introduced the Model T in 1908. While it was a fairly inexpensive automobile for the time, Ford was determined to further reduce the price in order to make the Model T available to the “great multitude.” As a result, the first automated assembly line was developed in 1913. Ford’s moving assembly line reduced the time it took to produce an entire car from 12 hours to less than three. By training his workers to complete just one step in an 84-step process in a standardized fashion, Ford dramatically increased production and efficiency in his factories. Today, manufacturers still are taking cues from Ford, streamlining their production processes to create standardized parts and increase efficiency.

“Before Henry Ford, a car was built by an individual or a group of individuals,” said Geoff Luther, CEO and owner of A-1 Tool Corporation, Melrose Park, Illinois. “This is very similar to the way molds are built today. Ford recognized that by making standardized parts and using assembly lines and dividing labor into specialized tasks, he could mass-produce cars quicker, cheaper and with better quality.”

Like Ford, A-1 Tool recognizes the benefits of standardizing parts and breaking down labor. Over the last several years, the company has made changes to its production process to allow for greater production efficiency and increased mold quality.

“It started about 10 years ago,” explained President Mike Pohjola. “One of our machines lost all of its parameters, and we were unable to locate the backup copy. Due to its diminished ability, we decided to use that machine for squaring blocks only.”

For Luther and Pohjola, this decision sparked an “ah-ha” moment that would lead to a more specialized production process.

“Breaking down the labor process of that one machine led to marked improvement in efficiency, as well as reduction in the amount of training required to bring new employees up to speed,” explained Pohjola. “We decided to purchase more specialized, high-performance tooling and again, we saw improvement. The process evolved from there.”

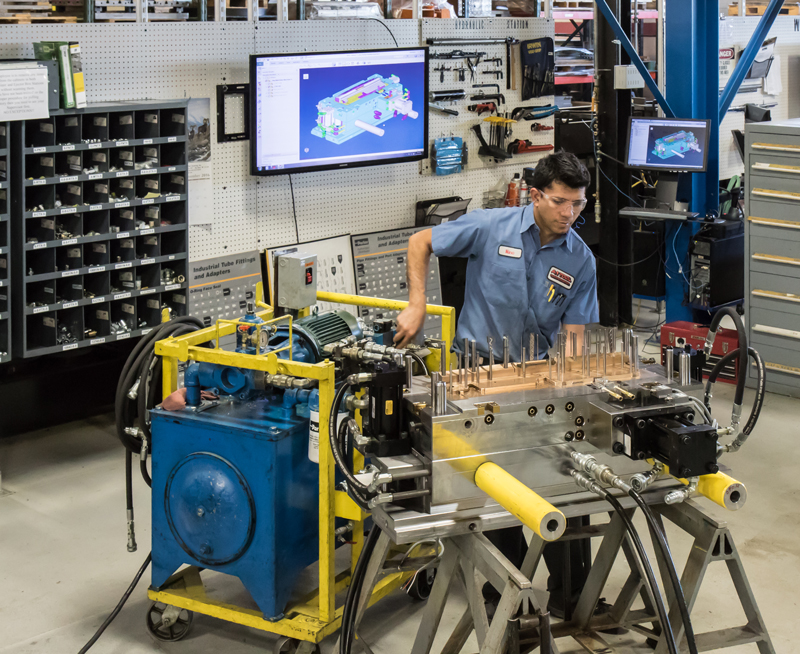

One of the most important parts of the process involves training experts in different areas of production. A-1 achieved this by developing specialized, individual work stations made up of smaller, simpler tasks. With each task broken down into smaller, simpler components, workers at each station become experts at their individual jobs, leading to improved speed and quality. Furthermore, the work stations have been developed as “lean” stations, containing only the equipment needed for each individual task, thereby creating further task efficiency.

“We created a custom scheduling solution which allows us to prioritize tasks,” Luther revealed. “We take every component from every mold, and we schedule every process for each one. We are able to prioritize when it needs to be completed, and it gets pushed and pulled through all of the individual stations.” Having these stations not only allows workers to get better at their jobs, but also holds everyone accountable. “The expectation is that everyone does their job and does it correctly,” he said.

Breaking production down to individual stations also has meant a breakdown of the training process. Now, systems and processes are redesigned into simpler tasks that workers perform repetitively, rather than every few days. This has the added benefit of not only developing experts, but also allowing supervisors to discern which workers are more qualified and more likely to perform well.

“It is important not only to qualify individuals, but to disqualify them as well,” remarked Luther. “The new training allows us to vet each individual on a lot quicker basis based on the employee’s work ethic and other factors.”

The price of training also is affected. “Rather than training an individual on all of the tasks needed to build an entire mold, the employee is trained on a subset of tasks,” explained Pohjola. Training is not the only cost benefit to this style of mold manufacturing. Workers become proficient not only at the task at hand but at the use of temperamental, high-priced, high-performance tooling. As a result, quality and efficiency goes up while the overall cost of tooling and rework goes down.

While the emphasis for workers is to become experts at their particular tasks, cross-training still is important, according to Pohjola. “When the shop is full of work, everything works really well,” he stated. “However, when the workload is light, it becomes a challenge to keep each work station busy, and you can end up with holes. That is where cross-training becomes crucial, enabling you to move people along with the work. There will still be a reduction in efficiency but there will be fewer workers standing around doing nothing.”

As mentioned earlier, the cost of tooling also can be affected. Luther explained that when the company decided to move to more assembly-line style manufacturing it decided to invest in better tooling, despite the fact it was more expensive and difficult to run.

“When you introduce this expensive, fussy tooling to the whole shop, you end up going through it like crazy,” remarked Pohjola, citing concerns with learning how to properly use the equipment. “But, once you only have a few workers using it, they become more proficient. It creates better utilization.”

Naturally, implementing this style of mold building was not without its challenges. For instance, according to Pohjola, wondering how far to take it? For A-1 Tool, the original plant layout wasn’t conducive to doing everything that was desired. With very large, expensive pieces of machinery, having a long and skinny shop building would have been ideal for putting everything in line. “We had to find a way to work around our size and space limitations,” stated Pohjola. “That was probably the biggest challenge.”

Another big challenge was with the workers themselves. People can prove naturally resistant and, “any time you have change, there will be issue,” said Pohjola. “Some people buy in immediately and are ready to work with a new system. Others fight right from the start. There is a lot of education and training that goes with something like this. Often, it is a complete change in culture and mindset,” he asserted.

Despite early challenges, A-1 Tool has reaped the benefits of assembly-line manufacturing. “It goes right back to engineering,” said Pohjola. “It goes from a highly custom built mold to a more manufactured mold. We are machining things to size and to fit.”

With everything broken down into smaller, simpler tasks, A-1 Tool is able to apply manufacturing principles used in Toyota, lean and 5S manufacturing, all of which play hand-in-hand with the principles of Ford-style manufacturing. “This type of manufacturing can be beneficial in a lot of ways. For any place with multiple, repetitive steps and lots of components, the same principles can be of use,” said Pohjola.

That’s not to say it would be appropriate everywhere. For instance, a small company with a smaller economic position may not be able to reasonably afford such a system. At a certain point, it would not pay off.

“It’s a direction we have taken, yet not all companies’ management or culture will have the same philosophies,” Luther affirmed.

While A-1 Tool’s Henry Ford-style production process was set in motion a decade ago, according to Luther and Pohjola, the last three years have taken it to a much higher level as the company continues to develop and adapt its process.

“We’ve gone down a road and explored a path,” said Luther. “One door opened and then another and it has been an evolution where, in the end, we had all of these pieces and it all started fitting together.”

According to Luther, the company still is in the middle of developing its process. There may have been some resistance or skepticism at first, but A-1 Tool has committed to its current path.

“We have a vision,” said Luther. “The pieces are in place, and we will continue to change and improve as needed. This is the direction we’ve chosen and we’re making it happen.”