Press release submitted on behalf of Meusburger.

Looking for high-quality plates? As standard parts manufacturer, Meusburger can provide the best possible support in this regard. With over 30 material grades stored on an area of 2.5 football fields and a high-percentage of in-house production, the best quality as well as process reliability and supply security are guaranteed.

Quality made in Austria

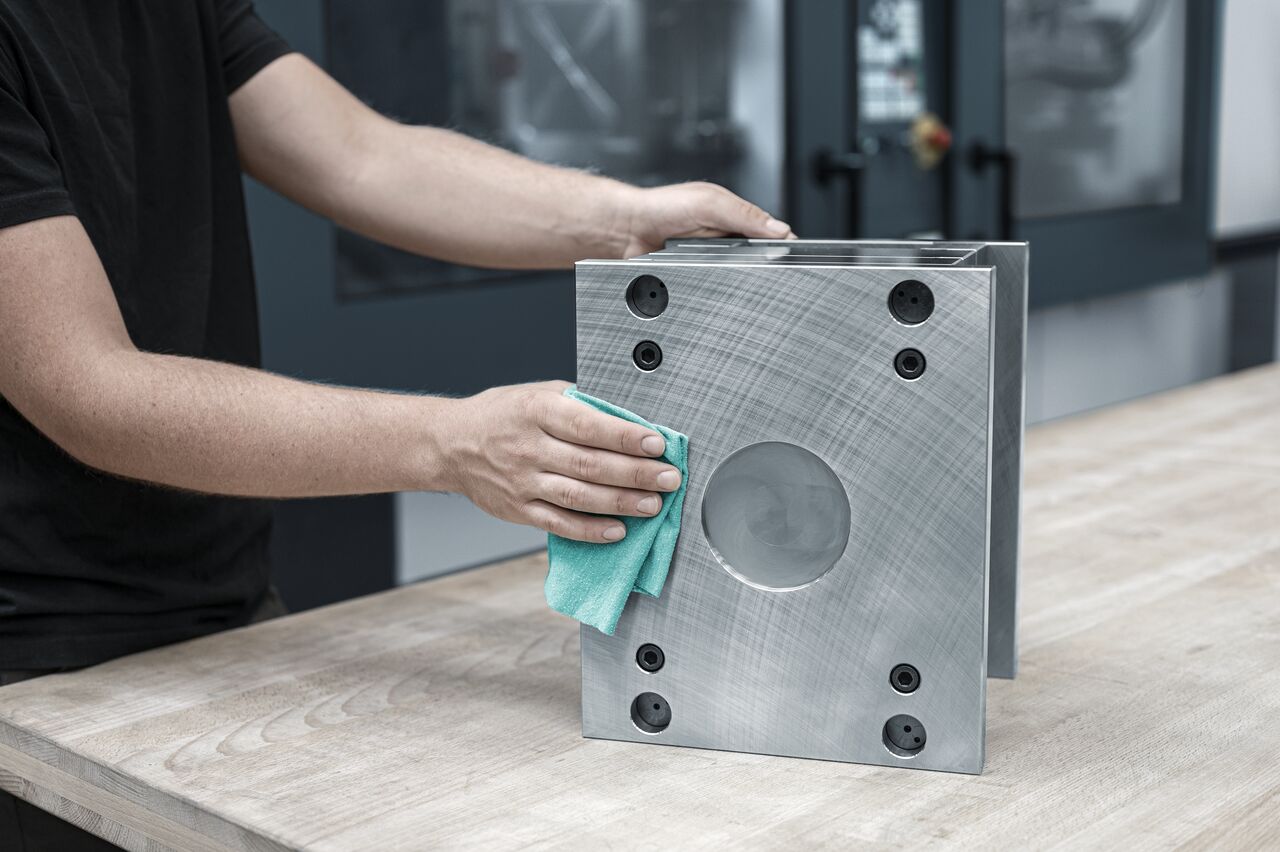

If customers are looking for high-quality plates that guarantee process reliability, then Meusburger is the right choice for them. Quality is of the utmost importance to the standard parts manufacturer, so the plates are manufactured 100% in-house in Austria. Highly automated production lines and optimally trained personnel guarantee quality in the μ range.

Process reliability in production

At Meusburger, in order to reach the best possible quality, the sheet metal first undergoes spectral analysis and a strength test. Then, even the best raw material is heat-treated for stress relief in the in-house furnaces. This creates optimum conditions for low-deformation processing of the parts. Hard points in the microstructure are eliminated, avoiding the risk of abrupt tool breakages. In many cases, the allowance necessary for further machining can be greatly reduced. The resulting shorter machining time and longer service life of the moulds save valuable production resources. However, stress-relieving heat treatment not only reduces lead times, but also increases precision because deformation is reduced to a minimum. This, in turn, leads to cost savings for customers and, in the long run, creates competitive advantages.

Continuous availability

The largest central standard parts warehouse is located at Meusburger headquarters in Austria. The majority of standard plates can be dispatched directly from stock, which offers customers decisive advantages. Moreover, customers benefit from a first-class ordering and delivery service and lose no time during the implementation of their projects.

Standardisation in mould making

Around 60 years of experience in working with steel and more than 110 different mould sizes make Meusburger a reliable and important partner in mould making. Customers benefit from the sophisticated standard parts range and from the numerous possibilities it offers:

- Mould sizes: 96 x 96 to 996 x 1196 mm

- Drilled and non-drilled plates

- Introduction of a cooling hole between guiding hole and screw connection possible

- Cavity plates with lever slots and alignment edge for an easy removal and fast alignment

- Wide and narrow versions of the ejector set (from mould size 196 x 196 mm) with matching risers

- Risers F 70 with thread for removal of the clamp plate together with the risers

Take a look at Meusburger’s plate range here: www.meusburger.com/plates-video

About Meusburger

Meusburger is the market leader in the field of high-precision standard parts. Customers all over the world make use of the advantages of standardisation and benefit from the company’s over 60 years of experience in working with steel. The product portfolio ranges from high-precision standard parts and selected products for workshop equipment to hot runner and control systems as well as a knowledge management system. This makes Meusburger the reliable global partner for making moulds, dies, jigs and fixtures.