Submitted by HASCO

The family-owned German company ARBURG is a machine manufacturer for plastics processing. The product portfolio comprises Allrounder injection moulding machines with clamping forces of between 125 and 6,500 kN, freeformers for industrial additive manufacturing, robot systems, customer and industry-specific turnkey solutions, plus the corresponding peripherals.

As a leading manufacturer of modular, high-quality standard mold components and customised hot runner systems, HASCO offers innovative and economical solutions for designers, moldmakers and injection moulders. With more than 100,000 products, HASCO is the full-service provider for moldmaking and supplies its customers with everything from a single source.

Both companies are well-known names in the plastics processing industry. But when and how did the market leaders come together with their specialty fields?

“When we at HASCO developed the modular system for mold units in the early 1960s, we oriented ourselves to the distances between tie bars that had been adopted by the leading injection molding machine manufacturer, ARBURG. Since then, all of HASCO’s standard plates have the uneven 6x dimensions such as 396 x 396 mm,”, explained Andrés Fragoso, head business development manager Europe at HASCO.

ARBURG has, for very many years, attached major importance to a high depth of production. For this reason, many components for the injection molding machines are manufactured in-house. Its own moldmaking department, which initially produced all the moulds itself, is now used predominantly for maintenance and repair work. Here, from the very beginning, ARBURG has counted on the full-service provider HASCO as its reliable supplier of standard mold components.

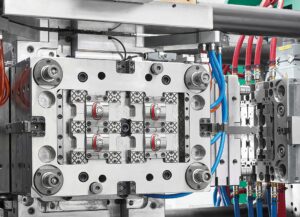

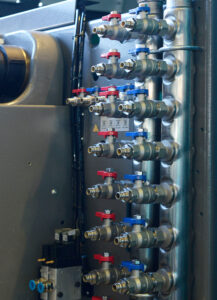

ARBURG machines with HASCO temperature control and cooling connections

Standardised components are also used on ARBURG’s machines for cooling and temperature control.

“In cooperation with HASCO, we equip the machines with complete, compactly integrated subassemblies consisting of tubes with standardised cooling connections etc. As a result, our customers can install their molds very quickly and easily, and thus minimise setting-up times,” Manuel Witte, head of the applications and industries department at ARBURG said. “In addition to the high quality and the excellent HASCO service, we appreciate very much indeed the constant further development that HASCO carries out on its products. We make increasing use of clean break temperature control connections made of stainless steel – and certainly not just for clean-room applications.”

For both companies, the customer benefit is of prime importance

Production efficiency in injection molding stands and falls with reliable temperature control. It is essential to offer the customers the highest quality products. “That ensures that they are optimally equipped to meet the specifications and requirements even in demanding fields such as medical, packaging and automotive,” adds Fragoso.

Growing trend towards turnkey projects

Optimum temperature control begins with the connections. It continues in the interior of the mold with other components for conformal cooling, core cooling, etc.

As a rule, ARBURG also equips the injection molding tools supplied as part of turnkey units with HASCO standard mold units as standard – and not just in the field of temperature control and cooling. Joint marketing teams from ARBURG and HASCO can also advise the customers – if they desire – on the optimum subassemblies from a technical and economical point of view.

“We offer our customers the added benefit of an integrated, perfectly coordinated system. This includes HASCO standard components for production of the mold units, temperature control and customised hot runner systems,” explains Manuel Witte.

Worldwide, one in every three projects at ARBURG is a turnkey project.

Innovative further developments

As market leaders in their respective fields, both companies are constantly working on the further development of their products. A constant exchange and trusting cooperation between the partners frequently leads to new ideas, innovations and improvements to the benefit of the joint customers.

“We regularly attend events or trade fairs where HASCO can introduce its latest developments,” said Witte. It is not rare for these new products to be subsequently tested at length in the ARBURG Technology Centre and, at the end of it all, to be launched on the market as the standard.

“ARBURG is naturally very close to the customer,” Walter Kiekert, technical sales engineer at HASCO, added. “In this way, we very often receive information about specific customer requirements, which we then take up in our ideas management team, evaluate them and integrate them into our development work.

This bilateral fostering of innovation leads time and again to genuine win-win situations for the customers and for the companies involved.

International cooperation

ARBURG believes that HASCO, its products, its quality, its service and its constructive cooperation. “When we need something”, Witte said, “we can rely on HASCO coming up with a solution very quickly indeed.”

Both companies maintain an excellent international network. Everywhere in the world, from Asia to America, where ARBURG has production sites with a Technology Centre, HASCO is not far away, thus making it possible to act quickly and easily there.

Over the past 60 years, it has been proven time and again that, when two market leaders cooperate, it creates invaluable benefits for the customers.