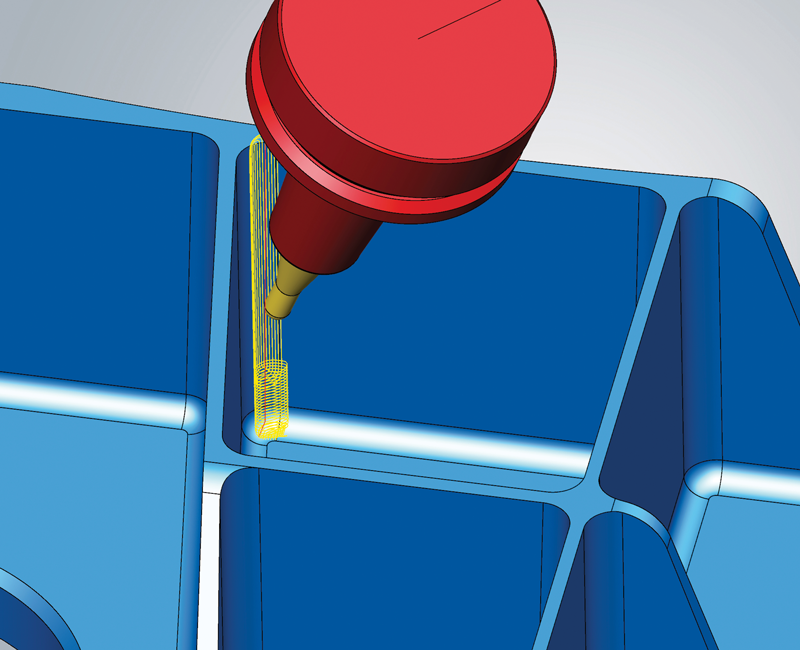

OPEN MIND Technologies AG, Needham, Massachusetts, has introduced hyperMILL® 2020.1, a new version of its comprehensive CAD/CAM software suite. In addition to 3D and 5-axis machining enhancements for complex part manufacture, the new version increases ease-of-use and overall programming performance, and includes key new automation and additive manufacturing strategies. hyperMILL® 2020.1 offers new Corner Rest Machining strategies for 3D and 5-axis techniques that provide significant benefits in complex machining applications, including mold and die. Enabled by a simple instruction, corners can be machined largely by vertical stroking motions. Then traditional z-level steps can be used to blend with the vertical section and the lower floor area. hyperMILL® 2020.1 also features a new 5-Axis Blade Tangent Milling strategy which increases efficiency when milling with conical barrel cutters that have a large primary angle. As a result, higher feed rates are possible, while avoiding center-cutting. The ADDITIVE Manufacturing process in hyperMILL® CAM software supports 3D printing / additive processes, including filling strategies for both planes and free-form shapes, and in 2D and 3D sections. Applications also include hybrid machining to fix damaged parts and additive machining of an existing component. For more information, visit www.openmind-tech.com.